Atlas F1 Technical Writer

Jordan have had everything against them this year, with an engine deal agreed very late and no budget to achieve much more than modifying the existing cars to deal with the Toyota engine and the new regulations. Atlas F1's Craig Scarborough looks at the details of the EJ15 and wonders if it should have been more accurately named the EJ14B

Last Year

After two long periods with Gary Anderson in charge of the technical side of the team, his final departure in 2003 put John McQuillam in charge. This resulted in a major redesign to the mechanical side of the chassis, moving to single keel to save weight and improve stiffness, yet retaining the main aerodynamic treatments. With a tight budget the car saw little development during the year - visual developments were limited to the unique shoulder wings set in front of the sidepod tops.

This Year

Late last year the team agreed a supply of Toyota engines. This engine deal partially secured the teams future and, around the same time and perhaps not coincidently, Mark Smith, one of Renault's chief designers, re-joined the team, bringing the team both a top level engine supply and design talent.

It has now been confirmed the EJ15 will be replaced by a Dallara-designed car for 2006, although it is not yet clear how the car will be built, developed and succeeded for 2007. With Jordan's wealth of resources now seeing better funding it would be a surprise to see them not being exploited. One minus side of the Dallara design for 2006 is the rapid departure of Mark Smith, apparently unhappy with being technical director of a team not designing their car, although a return of former Jordan lynch pin Gary Anderson has been rumoured.

With budget so tight and the engine and ownership deals arriving so late, the team were struggling to progress their design for 2005. The EJ14 was far from a successful car, with both handling and reliability issues, but the team have chosen to update the car to suit the new rules and engine.

Jordan were the first team to run a car to the regulations, with a lifted front wing, more forward mounted rear wing and revised diffuser. This interim car initially ran with a Cosworth engine, but needed revision in light of the Toyota engine.

Compounding their problems, Jordan have to get their old chassis, gearbox and aerodynamics working to cope with the additional horsepower coming from the new Toyota engine. Initial testing has been focussed as much on getting to know the new engine; checking cooling, testing the electronics, finding new gear ratios and set up data.

Mechanical and Engine

Unusually we will start with the mechanical elements of the newly numbered car (Jordan named the car the EJ15, rather than what it technically is – the EJ14B). With the late notice of the Toyota engine deal, and a limited budget, time was not available to redo the entire engine installation. Mounting a Formula One engine consists of the rear bulkhead interface, the gearbox interface, oil and water connections, and the electronics.

Cosworth place their engine mountings in different locations to Toyota, which make the first two mechanical installations problematic. The deal is for the supply of Toyota engines only - these will be standard RXV05 units, without modifications to the castings, to suit Jordan's installation requirements. The deal was also without gearboxes, so Jordan have to redesign their chassis to suit the new engine.

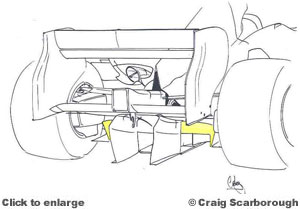

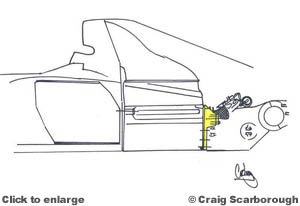

Mounting the engine to the gearbox requires eight fasteners, one behind each cam cover and the others down the sides to the sump; this is where the team have the largest problem in accommodating the Toyota engine. Without the time to redo the gearbox (one of the longest lead time components on an Formula One car) they have had to find another method to mate the two parts. Jordan has taken the pragmatic decision to use an adaptor plate (yellow), a technique used by many volume manufacturers to mate differing engine and gearboxes.

At the front the engines mounts in four places, one on each cam cover and a pair lower down on the sump. Re-bonding new mounts to the carbon fibre rear face of the monocoque is within the team's capabilities and timescales, but recalculating the load paths if they are in very different locations is a more complex operation. Having not seen the engine removed from the car, I cannot be sure how Jordan has tackled this problem.

The airbox and exhaust systems are revised for the installation, the latter still placing the outlets low and wide on the sidepods. Otherwise the gear casing appears similar, with the rockers operating coil-sprung dampers and a rear slung third spring and damper.

The main monocoque is largely carried over from the EJ14, as are the main design features. The car still adopts the triple keel set up, with a single forward keel and the rear pair split on either side of the chassis. Under the chassis are two large square slabs of ballast, curiously in differing materials; this could be to react to the lighter engine or lighter drivers to meet the 605 kilo minimum weight limit.

Aerodynamics

Looking at the car's aerodynamic features will be more like a review from 2004; the car has used wing profiles from 2004, albeit with the front wing using a deeper middle chord, achieved by bonding an extra fillet to an old design. Of course the mounting plates are shorter, to raise the wing the extra 50mm, but otherwise the whole wing, bargeboard and nose cone treatment is carried over from last year.

The sidepods are externally unmodified, with shoulder wings introduced mid season last year. Internally the radiator layout follows the previous EJ14 Cosworth set up; from my view of the car it wasn't possible to assess if these are sized differently to the Cosworth installation.

The vertical face created behind the diffuser would act like a (very) large gurney, which some other teams have adopted, but the sheer area formed, and the amount of reversed flow formed in its wake, would surely cause more drag than desired.

The rear endplates adopt an attractive profile in sweeping forwards to mount the wing, also carried over from the EJ14. Detailing of the trailing edge sees a scallop and lip to shape the flow trailing from the wing tip.

In testing a new rear wing endplate arrangement was tried, with a very different shape sweeping backwards from a narrower mounting, with the lower beam to reach back to the maximum length. This design meets both the regulations demands for the rear edge and total surface area.

After enduring a tough 2004 season and winter, Jordan has emerged in the new year with revived hopes based around new ownership and a new engine deal, although these deals only promise rewards in the medium to long term. For at least the opening flyaway races, and even the balance of 2005, Jordan's fortunes are going to be hindered by the lack of money in the past years. The new car is in fact far from new - it is instead an interim car with hastily modified aerodynamics and engine installation. In this technical summary we review what little has changed and what has been carried over.

After enduring a tough 2004 season and winter, Jordan has emerged in the new year with revived hopes based around new ownership and a new engine deal, although these deals only promise rewards in the medium to long term. For at least the opening flyaway races, and even the balance of 2005, Jordan's fortunes are going to be hindered by the lack of money in the past years. The new car is in fact far from new - it is instead an interim car with hastily modified aerodynamics and engine installation. In this technical summary we review what little has changed and what has been carried over.

At the beginning of this year the deal with Alex Schnaider's Midland F1 was confirmed. This truly secured the teams' financial future, and this was a deal that brought technical changes - Midland had been planning to enter Formula One directly, and as a result have been working with the Italian company Dallara for their first car. Despite their limited budget, Jordan has a serious Formula One production facility with autoclaves, seven-post rig and even a wind tunnel - these resources have produced complete Formula One chassis since 1991, with some success during the teams' high points.

At the beginning of this year the deal with Alex Schnaider's Midland F1 was confirmed. This truly secured the teams' financial future, and this was a deal that brought technical changes - Midland had been planning to enter Formula One directly, and as a result have been working with the Italian company Dallara for their first car. Despite their limited budget, Jordan has a serious Formula One production facility with autoclaves, seven-post rig and even a wind tunnel - these resources have produced complete Formula One chassis since 1991, with some success during the teams' high points.

Before his departure Mark Smith had set to work on developing updates for the car beyond the modified versions seen over winter testing. These developments should still be valid, but may not be seen on the car until the European races. In the mean time the car will struggle over its rivals with cars designed specifically for the new rules.

Before his departure Mark Smith had set to work on developing updates for the car beyond the modified versions seen over winter testing. These developments should still be valid, but may not be seen on the car until the European races. In the mean time the car will struggle over its rivals with cars designed specifically for the new rules.

The rest of the sidepod aerodynamic treatment is carried over, leaving only the floor and diffuser revised. Curiously Jordan revised their diffuser to meet the new rules demanding lower outer tunnels in a new way; rather than moulding a new floor with lower outer tunnels, the team have blanked off the old (2004) higher tunnels, leaving a void in between them. It isn't clear if this meets the wording of the rules, but its debateable if the design is a performance advantage.

The rest of the sidepod aerodynamic treatment is carried over, leaving only the floor and diffuser revised. Curiously Jordan revised their diffuser to meet the new rules demanding lower outer tunnels in a new way; rather than moulding a new floor with lower outer tunnels, the team have blanked off the old (2004) higher tunnels, leaving a void in between them. It isn't clear if this meets the wording of the rules, but its debateable if the design is a performance advantage.

|

Contact the Author Contact the Editor |

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 11, Issue 7

Articles

Interview with Narain Karthikeyan

Formula One's Tobacco Addiction

Technical Analysis: Jordan EJ15

Regular Columns

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |