Atlas F1 Technical Writer

Despite several sweeping changes to the regulations, few of them will affect the technical side of Formula One at the season opening Australian Grand Prix in ten days time. However, the teams will have to face the challenge of having to cope with a ban of electronics from the British Grand Prix onwards. Atlas F1's technical writer Craig Scarborough reviews the changes, the 2003 field, and how the teams will cope with the new rules

Regardless of the rule changes the cars were designed to create the usual advances in downforce, stiffness and weight reduction, and the nine definitive 2003 cars launched so far have proven to be similar to their immediate predecessors. Improvements, of course, have all been made, mostly through a lot of small incremental gains; no one has found the big new idea to leap ahead of the others. Below are the areas of design where changes have been made for the coming season, with a team by team review.

Areas of Design

Aerodynamics

With the aerodynamic regulations remaining stable for several seasons the losses from the 2001 front wing height regulation have been recovered, and then some. The teams have reached the stage where front downforce is now sufficient to match and balance that at the rear. In 2002 Ferrari were the first team to focus once more on downforce created at the rear of the car, the slimmer and lower rear end of the F2003 created more downforce and, crucially, the entire aero design was able work as the cars attitude on the track changed (that is, affected by pitch, roll or yaw). This driver friendly non-sensitive creation of a large amount of downforce allowed Ferrari to outpace all other cars under any conditions. As a result the other teams have redone their sums in understanding what was required from their cars for 2003, namely more downforce front to rear, and less sensitivity. These changes are largely in the detail design of the front wing and endplates, the rear wing, the diffuser and the sidepods. As result the emphasis on twin keels and nose shapes was less of a factor, and teams simply optimised these over the previous designs. This has resulted in many cars looking similar to those from last year.

Endplates attached to the front wing continue the format of sweeping in from the broadest width possible at the front to in between the front wheels. This improves the wings effectiveness when the front wheels turn sharply in a fast corner, and comes as a direct result of wind tunnel testing with steered front wheels, which is now as common place as testing the car at different attitudes to the ground.

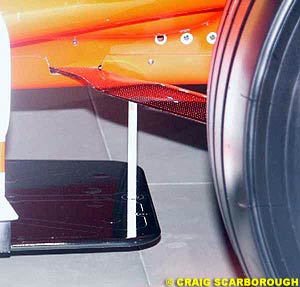

Few teams have adopted rears as radical as Ferrari's F2002, but more overall effort has been put into slimming this area, reducing both drag and created a low pressure area above the diffuser, as well as reducing air spilling over the floor into the diffuser. To keep this area slim more attention was needed on the cooling outlets, which are usually formed by the rear of the sidepods. Wider adoption of chimneys and other hot air outlets reduces the requirement for a wide outlet at the rear of the sidepod. Within the now smaller sidepods the requirement to route a specific length of exhaust has pushed the outlet up periscope style above the sidepod, while the neat trick of covering this exhaust with a faring to vent hot air from the radiators reduces drag to the frontal area of the two outlets, and the fast flow from the exhaust also actively pulls air from within the sidepod.

The last remaining area to create downforce is the rear of the car; this work is split between the wing, its lower mount and the diffuser. The proportioning of downforce between the three is almost impossible to extract as they all interact with each other, and their sum is greater than their individual performances. Rear wings switch between triple plane and bi-plane configurations, where three elements in a row constitute a triple set up, and two elements in a row with the third placed above them forms a bi-plane arrangement. Again the benefit in downforce/drag between two types varies between teams, but the rule of thumb is bi-planes create more downforce for greater drag due the effect of the higher element acting on the lower two, while the triple layout keeps the air flowing faster over the wing reducing drag but not creating the same amount of downforce. Again detail development makes the rear wings uninteresting to look at, but now the teams are experimenting with 3D wings, where the shape of the wing varies across its width. Jordan and Renault have run them recently, with Williams also running one in testing. They take advantage of the cleaner flow towards the sides of the wing that is not affected by the tall rollover structure area in the centre of the car.

Mechanical/Chassis

With CFD accelerating aerodynamic development simulation software is now making the development of chassis behaviour a higher priority for the teams. Vehicle dynamics is the term given to this field, and it focuses on how the mechanical layout and set-up of the car affects lap times. There is now a real correlation between the computer's figures and the real car, and these tools are used both at the design stage as well as by the race engineers when setting the car up at the track.

The results of these simulations are seen when the designers are as preoccupied with the positioning of the Centre of Gravity (CofG) as with the aero gains, although the mechanical design of the car can now take longer, if it is at all possible to change. This year the teams are trying to move weight to the rear of the car, while also lowering the weight in the car. This gives the rear tyres more grip and reduces tyre wear.

New engine and gearbox designs are fundamental in lowering the CofG, affecting the wheelbase (distance between the front and rear wheel) and the placement of the engine/gearbox along the car with regard to weight distribution. Williams moved weight backwards by shortening the rear of the car; Ferrari shortened the rear and lengthened the front to keep the same wheelbase, but with a rearward weight distribution.

Every weight saving on the car goes into ballast, and this includes the weight saving from improved use of carbon fibre in the chassis and impact protection. Several kilos are shaved from the chassis each time its design is revised, yet this still leaves a stiff chassis and crash resistant impact structures.

Engines

As with the chassis and aerodynamics there were to be no rule changes involving engines this year, ahead of the one engine rule change for 2004. With electronics in the engine being restricted and in the longer term long life engines being considered this could be the last year of full power, high revving V10s.

Seven manufacturers provide the supply of engines to the ten teams, with three teams getting customer supplies of older engines. Regulations limit the capacity, layout and materials for the engines, yet there's a remarkable spread of power outputs and speeds across the manufacturers. The average output is 875bhp at revs of 18.750rpm, with BMW having the top rev ceiling at 19.000+, although Ferrari were tipped to have the more powerful engine for most of last year at almost 900bhp. Mercedes and Toyota were rated next in power output, while the Honda and Ford were respectable, leaving Renault with the lowest output as a result of their attempts to make an intrinsically unreliable concept reliable.

While the engine designers would like to design an engine that only ever sat on the dyno, the chassis designers are pressing the engine manufacturers hard for an engine optimised for installation in a race car. This requires low overall weight, low CofG, stiff casings and low cooling requirements, almost all of which affect either performance or reliability of the engine. As a result the teams all seek an exclusive agreement with an engine supplier, so that they can work together to design the engine specifically for their car. Renault have gone the furthest with their wide angle concept, but all engines place their mountings, cooling outlets and airbox shapes according to the chassis designers demands. Ballpark weight for an engine is less than 100Kgs, and chassis designers are not concerned with lowering that figure any further, preferring to keep increased stiffness and lower CofG from the installation.

Lowering the CofG used to be dependant on clutch diameter, but these days the clutches are smaller than the crank throws and the crank cannot be lowered any further. Instead the reduction of weight at the top of the engine is key, with cylinder head castings and cam locations refined to lose as much weight form here as possible with out sacrificing reliability or stiffness, and weight added to the crankcases is acting both as permanent ballast as well as making a stiffer set up. V-angles have been optimised at 90 degrees, which provides both a low engine and a natural balance to reduce vibrations. Renault are the sole supplier to go beyond that angle, and the gain is a 5-6cms lower CofG compared to a 90 degree unit.

Gearbox

The outer casing varies tremendously across the teams; the main element being stiffness, lightness and positioning of mounting points for the suspension. Hence the material for the gearbox is critical factor; aluminium castings have long been favoured, although Ferrari followed Minardi in using cast titanium casings. Prior to that Ferrari used carbon fibre/titanium in a two-piece design, which has been revived this year. Last year Arrows succeeded in using a carbon fibre casing, and some teams have looked into this strategy according to rumours.

Weekend Strategy

With the cars being secured in parc ferme in between the qualifying and the race the teams will need to start the race with the same set up and fuel load as used in qualifying. While this gives the mechanics a Saturday night out, it does leave the race engineers thinking about strategy for qualifying and the race.

A good qualifying set up will leave the car wearing its tyres and driver out in the race and needing to pit stop within the first few laps, although a good race set up will leave the car hobbling on its qualifying run and at the back of the grid come race day. With limited overtaking on most circuits a preference towards a qualifying set up will be chosen, with few tracks suiting a better race set up.

Tyres

Again Bridgestone have Ferrari as their primary team and the others as effectively customer teams, while Michelin have Williams, McLaren and Renault as primary teams and the others as customers. Should the bespoke option be taken up Michelin will have the greater task on their hands with three times the number of primary teams. This could mean the long suffering Bridgestone teams have tyres designed for something other than a Ferrari.

With Renault, Jordan and Minardi (plus perhaps Jaguar) taking up Friday testing, these teams can run three cars for a lot of laps and tyres to evaluate the track conditions, and Renault has suggested the third car will be an expensive track sweeper. Some data from these teams will be fed back to the other teams to help them make tyre judgements. With the remaining teams having less track time they will be short on time to choose a tyre for qualifying and the race, which is why the cars have permanently fitted tyre temperature devices set into the bodywork; it aids chassis set up. McLaren have gone so far as to mount infrared cameras to the cars to monitor each tyres temperature.

With the tyre war getting tighter, the teams having lots more downforce, and the race tyre running in qualifying compounds will get even softer, and lap times will reduce at an even greater rate then before.

Electronis

With an imminent ban on launch and traction control we may see some teams move up and down the grid a little as their advantages are reduced. The teams will need to re-evaluate their cars set-up and probably place more weight and downforce on the rear of the car to inhibit wheel spin. What the redundant engineers will work on is debateable; cheating is out of the question, but knowledge gained from researching electronic driver aids can be fed back in to simulation software to assess what mechanical means can be adopted to recoups the losses.

Team by Team

Ferrari

As an evolutionary development of the previous car the design team have obviously made gains over those previously achieved. Working on the dynamics strengths of the F2002 weight has been moved backwards, with a shorter gearbox and longer chassis, leaving the wheelbase at a similar length. Aerodynamically the sidepods adopt slimmer front profiles, with the lower side impacts structures sticking out, and this improves the flow from the splitter under the chassis, an echo of the twin-floored Ferraris from the early nineties. Within the curved sidepods are compound angled radiators, with an even more complex (albeit flat) shape. A slimmer rear end is hidden by new flip-ups folding in between rear wheels, while the exhaust outlet is still faired in by a cooling outlet, with a longer lip on its outer edge.

In order to package the suspension geometry with the shorter cast titanium gearbox the front of the wishbones mount almost on the rear of the engine. Following the theme of last year the gearbox is now fully faired-in, so the air passing from within the sidepods gets a smooth passage through the rear of the car, and on top of the gearbox the familiar damper layout is retained. In keeping with the evolutionary theme the engine has been improved without any radical developments, and as usual Ferrari showed a clear image of the engine to the press.

Williams

At their launch the car's bargeboard philosophy had changed, although it is undecided whether large mid-placed or forward mounted boards are going to be used for the initial race set up for the car. Several wing variations have been seen during testing, including a flat front wing and a 3D rear wing. Boxy cockpit treatment is retained, and is partially to accommodate the huge airbox over the engine. The engine cover accordingly drops off sharply to cover the dampers, which still use coil over sprung dampers, a blade type anti rollbar and a separate third damper.

Mechanically the front of the car has low mounted torsion bars to improve CofG and an unusual (possibly hydraulic) front suspension set up has been seen in testing.

McLaren

The MP4/18 is still under design, and is reliably believed to have a carbon fibre gearbox designed in cooperation between Mike Coughlan (Ex Arrows designer and carbon Fibre gear expert) and John Sutton (ex-Ferrari gearbox designer). Rule changes over the winter have suggested that the 18 will undergo a further design phase to optimise it for the new non-electronic rules, although this remains to be confirmed by the team.

Renault

Jean Jacques-His said the car was "entirely new from the fuel cell backwards". The rear end developed over a two year period incorporates the engine, gearbox and rear bulkhead. The engine retains the same wide angle, advertised as 111 degrees but now widely regarded (but not confirmed) as 106 degrees. To ward off unwanted vibrations caused by this unbalanced layout Renault have stiffened the lower crankcase, added a radical valve drive and counter balancer set up, and lightened the cylinder heads.

The engine now mounts to a carbon and titanium gearbox, similar to the layout used by Ferrari until last year, with the carbon fibre bell housing upper section mounts to the suspension and dampers, while the gear cluster sits inside a titanium casing. Pull type dampers are used to push the weight forward, and the vertical two-piece torsion bars lower the CofG penalty of the high mounted dampers. The gearbox is still tied to the rear of the chassis with a simple pair of tubular struts to retain stiffness, eschewing what Gascoyne sees as unnecessarily complex 'structural' carbon fibre set ups.

Sauber

Ferrari has provided their 2002 engine for Sauber in 2003, and the technical support for Sauber to install it. The material and technical assistance ends there, and Sauber have to design their own airbox, gearbox and exhausts. The lower engine is mated to a new gearbox still retaining vertical torsion bars and a simple three damper set up. The rear wishbones were part metal (lower) and part carbon (upper) on the launch car. Exhausts are still slash cut at their exits rather than the vertical outlets seen on the Ferrari last year, but Sauber have raised their exits above the lower engine cover, necessitating heat shields being added to the sidepod tops.

The cockpit has been revised to allow the taller Frentzen to fit in, having had problems in testing in the C21. This was less to do with his height, but rather the electronic boxes installed either side of the base of the seat that would not allow Frentzen's rear to fit, and these have been relocated.

Jordan

Now under Henri Durand's direction, the new car makes use of Ford's 72 degree customer engine. While not a low line engine, it is very slim and remarkably low. The effect of this can be seen with the engine cover, which looks more like a snorkel coming out of the sidepod tops than the usual roll structure and airbox cover. The sidepods feature inlets and wing treatments seen on the EJ12, reinforcing the lack of change on the new car.

At the front the twin keel set up is retained, with a nose more horizontal than the anteater design in 2002. The front keels now splay out at 45degrees to match the front wing mounts, and there doesn't appear to be a strut supporting the two keels, so progress has been made in the structures departments in keeping the set up stiff.

Jaguar

The new Jaguar discards the tricycle Keel set up and adopts the proven single 'tandem' keel design. A conventional front wing with endplates echoing the Renault's, with mini diffusers on the outer edges, is due in part to the ex-Renault head of aerodynamics Ben Aganethelou, as is the barge board shape. Sidepods sweep in tightly along the lower edges to a slim coke bottle shape, while the complex flip-up hot air outlet set up in front of the rear wheels makes the rear look bulky. A major change is the tidy cockpit surround, now much sleeker, resulting in a roll structure almost vertical at the sides in order to present the smallest frontal area in front of the rear wing.

While the chassis has made new from old, the engine really is all new, with Cosworth developing a new engine using a 90 degree V-angle. The CR5 uses new heads, blocks and ancillaries to produce a lighter, lower and more powerful series of engines. Winter testing has seen the engine fail repeatedly, but the pressure of engine swaps has lead the team to leave their security screens open, allowing clear views of the engine as it is wheeled out to the back of the garage for a replacement. On close observation the heads have been severely waisted, with the cam cover appearing like a shrink-wrapped casting over the cams, while the airbox is small and appears almost sucked in to the inlets.

Mated to the lower engine is a lower gearbox, which still retains the coil over sprung dampers and a T-bar set up anti rollbar, and the third damper seen for over two years on Jaguars. However, in a philosophy reversal the rear suspension now uses two simple wishbones over the multi-link arrangement used since the Stewart days.

BAR

The nose is higher and has greater ground clearance all the way back to the sidepods. The sidepods themselves drop the boxy Volvo-like side impact structures for sleek fronted sidepods sweeping in and down to a very tight rear end. Cooling is afforded by both optional chimneys and a T-shaped outlet formed by the rear of the sidepods. The exhaust system projects from the sidepod tops, but does not feature a hot air outlet for the radiators, placing the oval section outlet horizontally rather than the vertical outlets seen on the Ferrari.

The diffuser adopts the Ferrari practice of a steeper section at the start of the outer tunnels. The gain in this design is not fully understood outside of the aero departments of the various F1 teams, but the more abrupt change from flat floor to diffuser is said to generate a stronger, if less tidy, flow into the diffuser. The damper set up front and rear is new, with an all carbon suspension, while the new alloy gearbox places the dampers inside and operates a simpler anti-roll-bar/third damper set up.

As a result of having only one team to support, and in light of criticism in 2002, Honda have stepped up their game with a largely new engine. Lighter, lower and more powerful, Honda were happily touting figures of 20Kg weight savings and 19.000rpm crank speed at the launch. While the companies input will be considerable the quoted gains have to be viewed suspiciously.

Minardi

The new car carries over much of the PS02s design, although the nose have been further raised along its full length. Sidepods have been raised at the front and then swept to a lower and narrower coke bottle shape. Combined exhaust/hot air outlets have been adopted, allowing simpler flip ups in front of the rear wheels, plus the engine cover has been made lower over the airbox. The wings retain shapes from 2002, and it is doubtful these will be updated before the European season, given the restrictions the car was designed around.

Toyota

Mechanically the car is all new. A third damper suspension has also been added to the front, along with all carbon suspension and a new power steering system. A new gearbox was also installed, using seven speeds in an alloy casing. Dampers have been moved from either side of the casing and placed inside, operated via a horizontal torsion bar and Brunner's trademark scissor type anti rollbar as well as the third damper.

Engine development has been evolutionary, with lowering of the CofG being a prime concern. A radical cylinder head shape moulds the casing over the pairs of cams, and choice of materials has been carefully considered, although no 'exotic' materials have been used. In fact one material specification came from World War II.

A strange situation has arisen regarding the technicalities of the cars for the 2003 season. The design process dates back as far as last May for some teams, at which time there were almost no rule changes affecting the cars, which lasted until the FIA revealed two sets of regulation changes late last year and early this year. The first affected the sporting side of the championship and the way the cars are run, while the second set, announced just as the first two cars were unveiled, hit the electronics side of the cars heavily, and the operation of the cars over the Grand Prix weekend even more so. These far reaching changes were aimed at achieving cost savings and improving the spectacle, but they will have almost no effect of the cars themselves until Silverstone, when the ban on Traction and Launch control commences. Even then there will be no visual changes except when the cars are running; they will be able to slew sideways under careless acceleration.

Recent front wing design has pushed towards regaining lost downforce, and curved designs with a lower centre section recovered a lot of lost grip. This came at a price, as the lower centre section is more sensitive to ride height changes. With the detailed development of wing profiles, and shapes being accelerated by accurate CFD modelling rather than long drawn out windtunnel testing, the same downforce figures can be found with flatter wing shapes, and without the implied pitch-sensitivity. Wing shapes seen during later testing sessions this year have significantly flatter shapes, and some even have slight rises in the middle. This could prove beneficial, as the smoother flow from the centre of the front wing goes both under the floor to the diffuser as well as over the centre of the car, improving the function of these very sensitive aerodynamic areas.

Recent front wing design has pushed towards regaining lost downforce, and curved designs with a lower centre section recovered a lot of lost grip. This came at a price, as the lower centre section is more sensitive to ride height changes. With the detailed development of wing profiles, and shapes being accelerated by accurate CFD modelling rather than long drawn out windtunnel testing, the same downforce figures can be found with flatter wing shapes, and without the implied pitch-sensitivity. Wing shapes seen during later testing sessions this year have significantly flatter shapes, and some even have slight rises in the middle. This could prove beneficial, as the smoother flow from the centre of the front wing goes both under the floor to the diffuser as well as over the centre of the car, improving the function of these very sensitive aerodynamic areas.

As already mentioned the improvements in front wing design has lessened the need for twin keels and radical bargeboard treatments to create downforce. While Sauber and Jordan have retained their twin keels, most other teams have opted for a single keel. Single keels can also be sub-divided into two groups; tandem and forward keels. Tandem keels fix both the inboard wishbone mounts on one long keel, hence the mounts along the centreline of the car, and the wishbone can be made in one piece resembling a diamond shape. Forward keels fix only the front wishbone mounts on a keel with the rear of the wishbone fixed directly onto the chassis. This set up requires the underside of the chassis to be lower towards the rear, but is a better structural design at the cost of some aerodynamic efficiency.

As already mentioned the improvements in front wing design has lessened the need for twin keels and radical bargeboard treatments to create downforce. While Sauber and Jordan have retained their twin keels, most other teams have opted for a single keel. Single keels can also be sub-divided into two groups; tandem and forward keels. Tandem keels fix both the inboard wishbone mounts on one long keel, hence the mounts along the centreline of the car, and the wishbone can be made in one piece resembling a diamond shape. Forward keels fix only the front wishbone mounts on a keel with the rear of the wishbone fixed directly onto the chassis. This set up requires the underside of the chassis to be lower towards the rear, but is a better structural design at the cost of some aerodynamic efficiency.

With the track changes making the Hockenheimring a lot slower and Hungary becoming a lot quicker, Monaco is now the sole slow track, while only Indy and Monza remain as fast, wide open tracks. The teams now need to consider whether special wing sets for these races are economical. Last year few teams had special wings for Monaco, and there were few unique wings run at Monza.

With the track changes making the Hockenheimring a lot slower and Hungary becoming a lot quicker, Monaco is now the sole slow track, while only Indy and Monza remain as fast, wide open tracks. The teams now need to consider whether special wing sets for these races are economical. Last year few teams had special wings for Monaco, and there were few unique wings run at Monza.

With the minimum weight of the car specified in the rules, teams have had to add weight in the form of ballast to the cars if they are underweight. At first this sounds absurd; if weight were to be reapportioned, components would be better off being made heavier, cheaper or more reliable. Yet the teams have long discovered that a car well under the weight limit, could use ballast low down in the car to reduce CofG and move it front to rear to tune weight distribution. These days the ballpark figure is around 85kg of Ballast for a car weighing no more than 600kg, which is nearly 15% of the cars weight. This gets placed in the floor along side the chassis or gearbox and in the splitter under the drivers knees. This year Ferrari have gone so far as to pack the splitter with cake-like slices of ballast and spray it black to hide the fact that so much ballast is placed there.

With the minimum weight of the car specified in the rules, teams have had to add weight in the form of ballast to the cars if they are underweight. At first this sounds absurd; if weight were to be reapportioned, components would be better off being made heavier, cheaper or more reliable. Yet the teams have long discovered that a car well under the weight limit, could use ballast low down in the car to reduce CofG and move it front to rear to tune weight distribution. These days the ballpark figure is around 85kg of Ballast for a car weighing no more than 600kg, which is nearly 15% of the cars weight. This gets placed in the floor along side the chassis or gearbox and in the splitter under the drivers knees. This year Ferrari have gone so far as to pack the splitter with cake-like slices of ballast and spray it black to hide the fact that so much ballast is placed there.

One simplification of the chassis moulds has resulted in a simple but effective change in the tow arrangement for the car. This used to be a slot moulded through the fuel tank area of the chassis for the tow loop to be passed through, but last year McLaren realised that this weighty slot could be replaced with an external towing eye formed under the intake above the driver head, with a metal bar affixing to the chassis moulding. Most teams have adopted this simple design this year.

One simplification of the chassis moulds has resulted in a simple but effective change in the tow arrangement for the car. This used to be a slot moulded through the fuel tank area of the chassis for the tow loop to be passed through, but last year McLaren realised that this weighty slot could be replaced with an external towing eye formed under the intake above the driver head, with a metal bar affixing to the chassis moulding. Most teams have adopted this simple design this year.

This year many engines are expected to near 19.000rpm, depending on how the new qualifying rules are approached. Speed is not expected to reach beyond existing limits, as increased efficiency needs to be gained in the extremely short combustion period at the highest revs. One engine designer told me at 19.000rpm an F1 engine should be producing nearer 950bhp if it is efficient, and that is the target for most designers this year.

This year many engines are expected to near 19.000rpm, depending on how the new qualifying rules are approached. Speed is not expected to reach beyond existing limits, as increased efficiency needs to be gained in the extremely short combustion period at the highest revs. One engine designer told me at 19.000rpm an F1 engine should be producing nearer 950bhp if it is efficient, and that is the target for most designers this year.

Gearboxes used to be a design element that remained unchanged for several years, although changing demands of engine and chassis design has now reduced that to a year. As with engines the technology of the gearbox internals is consistent across the teams, with 6-7 (plus reverse) speeds being operated sequentially by a selector drum operated by the cars electro-hydraulics. The detail of the design changes constantly, with the size of components continually reduced to a minimum.

Gearboxes used to be a design element that remained unchanged for several years, although changing demands of engine and chassis design has now reduced that to a year. As with engines the technology of the gearbox internals is consistent across the teams, with 6-7 (plus reverse) speeds being operated sequentially by a selector drum operated by the cars electro-hydraulics. The detail of the design changes constantly, with the size of components continually reduced to a minimum.

Both tyre suppliers have made great strides over the winter, and rule changes will allow teams to have two specifications of bespoke tyres provided for the weekend. Whether the suppliers have resources to ship so many sets of bespoke tyres to each race remains to be seen.

Both tyre suppliers have made great strides over the winter, and rule changes will allow teams to have two specifications of bespoke tyres provided for the weekend. Whether the suppliers have resources to ship so many sets of bespoke tyres to each race remains to be seen.

The F2002 will probably run until Imola, albeit heavily revised with new front wing-endplates, rear brake ducts, plus a myriad of other detail revisions that should keep Ferrari on pace with the new cars not yet up to speed. Winter testing showed that the old car still has the best pace in the field, and the newly presented F2003GA will run from the start of the European races. While its pace is not in question reliability needs to be sorted, with for example hydraulic issues crippling the car in its first public test.

The F2002 will probably run until Imola, albeit heavily revised with new front wing-endplates, rear brake ducts, plus a myriad of other detail revisions that should keep Ferrari on pace with the new cars not yet up to speed. Winter testing showed that the old car still has the best pace in the field, and the newly presented F2003GA will run from the start of the European races. While its pace is not in question reliability needs to be sorted, with for example hydraulic issues crippling the car in its first public test.

After being accused of having a poor chassis in 2002 Williams have gone further in redesigning its car to match the reputation of BMW's engines. Visually the main departure for the team is that the long wheelbase has been dropped in favour of a shorter one, created by new shorter gearbox and chassis. In the front a new raised nose design keeps its cross-section to a minimum while hitting the maximum height permitted by the regulations. Sidepods are still low fronted and slimmer, despite retaining the vertical radiator layout from last year.

After being accused of having a poor chassis in 2002 Williams have gone further in redesigning its car to match the reputation of BMW's engines. Visually the main departure for the team is that the long wheelbase has been dropped in favour of a shorter one, created by new shorter gearbox and chassis. In the front a new raised nose design keeps its cross-section to a minimum while hitting the maximum height permitted by the regulations. Sidepods are still low fronted and slimmer, despite retaining the vertical radiator layout from last year.

Having decided the new car needs a lot more time to get the design right, McLaren have decided the MP4/17D will start season, updated from the MP4/17B run late last year. It uses a new gearbox and rear damper layout from a new damper manufacturer. In testing a unique front wing was repeatedly tried, with a high wide flat centre section and raised outer sections. The raised outer sections are further spaced than conventional wings and, theoretically at least, are less efficient, being further from the ground.

Having decided the new car needs a lot more time to get the design right, McLaren have decided the MP4/17D will start season, updated from the MP4/17B run late last year. It uses a new gearbox and rear damper layout from a new damper manufacturer. In testing a unique front wing was repeatedly tried, with a high wide flat centre section and raised outer sections. The raised outer sections are further spaced than conventional wings and, theoretically at least, are less efficient, being further from the ground.

An outwardly unchanged new car, the R23 was unveiled twice to the press and public, although the new car is actually a major departure from the R202 in its mechanical design. Aerodynamically, the R202 concept has been carried over, albeit with drooped nose and altered rear end, which is slimmer and includes new curvy hot air outlets. A new front wing uses endplates with Toyota-like pairs of flips on the outer edge, and the 3D rear wing has been retained, although like the hot air outlets it may alter in detail before Melbourne.

An outwardly unchanged new car, the R23 was unveiled twice to the press and public, although the new car is actually a major departure from the R202 in its mechanical design. Aerodynamically, the R202 concept has been carried over, albeit with drooped nose and altered rear end, which is slimmer and includes new curvy hot air outlets. A new front wing uses endplates with Toyota-like pairs of flips on the outer edge, and the 3D rear wing has been retained, although like the hot air outlets it may alter in detail before Melbourne.

Another car outwardly similar to its predecessor, the C22 is aerodynamically a big development from 2002. The twin keel nose is retained, but virtually unnoticed by observers is the height of the underside of the nose, which has been raised several inches to the point where the line of the upper wishbone only just passes through the main part of the chassis. This allows the flow from the front wing to be unhindered. Careful shaping of the floor in front of the sidepods is also new and neat. The sidepods are much slimmer and a lot lower towards the rear, afforded by the new engine from Ferrari and a new gearbox. In testing a flatter front wing has been tried, and Sauber have discarded their trademark open rear diffuser for a conventional 'boxed in' version, as designer Willi Rampf calls it.

Another car outwardly similar to its predecessor, the C22 is aerodynamically a big development from 2002. The twin keel nose is retained, but virtually unnoticed by observers is the height of the underside of the nose, which has been raised several inches to the point where the line of the upper wishbone only just passes through the main part of the chassis. This allows the flow from the front wing to be unhindered. Careful shaping of the floor in front of the sidepods is also new and neat. The sidepods are much slimmer and a lot lower towards the rear, afforded by the new engine from Ferrari and a new gearbox. In testing a flatter front wing has been tried, and Sauber have discarded their trademark open rear diffuser for a conventional 'boxed in' version, as designer Willi Rampf calls it.

Relatively late the new cars roll out due to the delayed receipt of their Ford RS (Cosworth) engine, Jordans initial problems may be more financial than technical. This would explain the few changes from the 2002 design seen on the EJ13 seen in testing.

Relatively late the new cars roll out due to the delayed receipt of their Ford RS (Cosworth) engine, Jordans initial problems may be more financial than technical. This would explain the few changes from the 2002 design seen on the EJ13 seen in testing.

Jaguar's fortunes don't seem to have risen since the started racing, with the car's design goals having been up and down every year so far. Last year's more radical car was the result of an overly conservative 2001 car, with its many failures leading to a more conservative car once again. Designed by an all-new technical team the R4 has simply set out to be a 'bug-fixed' R3. Many philosophies are carried over, but more rigorously checked and analysed during the design process.

Jaguar's fortunes don't seem to have risen since the started racing, with the car's design goals having been up and down every year so far. Last year's more radical car was the result of an overly conservative 2001 car, with its many failures leading to a more conservative car once again. Designed by an all-new technical team the R4 has simply set out to be a 'bug-fixed' R3. Many philosophies are carried over, but more rigorously checked and analysed during the design process.

After four designs stemming from 'production race car' designer Malcolm Oastler, BAR have placed ex-Williams aerodynamicist Geoff Willis in charge as Technical director. Although not previously accustomed to having responsibility for the full car Willis has overseen the biggest redesign on the grid this year. Little remains of the BAR004, other than some aerodynamic elements introduced in 2002 by Willis' aero team. While the obvious retention of Willis' trademark front mounted barge boards suggests the aero is unchanged, their detail design and the rest of the car is fundamentally new.

After four designs stemming from 'production race car' designer Malcolm Oastler, BAR have placed ex-Williams aerodynamicist Geoff Willis in charge as Technical director. Although not previously accustomed to having responsibility for the full car Willis has overseen the biggest redesign on the grid this year. Little remains of the BAR004, other than some aerodynamic elements introduced in 2002 by Willis' aero team. While the obvious retention of Willis' trademark front mounted barge boards suggests the aero is unchanged, their detail design and the rest of the car is fundamentally new.

Minardi were the last to release their car for testing as usual, and without a formal launch. Minardi now have a customer Ford engine, as do Jordan, and depending on its specification it may be the first time they have had a competitive engine for several seasons. Another similarity between Jordan and Minardi is that both do not have the financial resources to develop the car as much as they would like. It is common practice for Minardis to have only a few weeks windtunnel time each year, and even less track test days.

Minardi were the last to release their car for testing as usual, and without a formal launch. Minardi now have a customer Ford engine, as do Jordan, and depending on its specification it may be the first time they have had a competitive engine for several seasons. Another similarity between Jordan and Minardi is that both do not have the financial resources to develop the car as much as they would like. It is common practice for Minardis to have only a few weeks windtunnel time each year, and even less track test days.

Last season was good and bad for Toyota. They completed the season with points, gained a reputation for a fast and reliable engine, but had their chassis berated by every F1 pundit following the sport. Development on the TF102 was stopped early last year to focus on the new car, with some TF103 developments tried on the old car in the latter part of the season, confusing the development freeze to the outside observer. The new car is totally new, as last year's car retained several systems and features from the 2001 test car. Developed in Toyotas new wind tunnel, the nose has been raised and adopts a Ferrari/Renault like single 'tandem' keel, the sidepods are slightly narrower at the rear but a lot lower, sporting hot air outlets wrapped around the exhaust pipe, retaining the hot air outlets combined into the flip-ups in front of the rear wheels. The engine cover has been lowered, and now has large blister at its rear to cover the new third damper suspension set up.

Last season was good and bad for Toyota. They completed the season with points, gained a reputation for a fast and reliable engine, but had their chassis berated by every F1 pundit following the sport. Development on the TF102 was stopped early last year to focus on the new car, with some TF103 developments tried on the old car in the latter part of the season, confusing the development freeze to the outside observer. The new car is totally new, as last year's car retained several systems and features from the 2001 test car. Developed in Toyotas new wind tunnel, the nose has been raised and adopts a Ferrari/Renault like single 'tandem' keel, the sidepods are slightly narrower at the rear but a lot lower, sporting hot air outlets wrapped around the exhaust pipe, retaining the hot air outlets combined into the flip-ups in front of the rear wheels. The engine cover has been lowered, and now has large blister at its rear to cover the new third damper suspension set up.

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 9, Issue 9

Articles

Montoya & Williams: Can They Challenge?

Reflections on Mosley's Brave New World

Pencils at Dawn

The Cult of a Personality, IV

2003 Season Preview

2003 Drivers Preview

2003 Teams Preview

2003 Technical Preview

The 2003 Atlas F1 Gamble

Columns

Off-Season Strokes

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |