Atlas F1 Technical Writer

The lack of significant changes in the FIA's technical regulations for the 2002 season should allow for a more competitive season than last year's. It also allowed the engineering brains in Formula One to develop other areas of the car, other than aerodynamics. Atlas F1's technical writer Craig Scarborough reviews the changes and analyses the cars we'll be seeing on the grid next week

The lack of aerodynamic rule changes allows the teams to improve their designs from last year's changes to the front and rear wing regulations. Visible rule changes will be in the form of safety changes: larger rear view mirrors, larger rear lights and increased impact tests for the rear crash structure. A non visible change but nonetheless important, will be to the data transfer between the car and pits, which will now be two-way, allowing the team to make changes to the car's electronics from the garage and not from the buttons on the steering wheel.

A major deciding factor in the teams' competitiveness this year will be tyres. Last year, Michelin were learning their ropes and the French-shod teams were learning what it took to get the tyres to perform.

Design-wise, some teams have opted for riskier technical solutions, with radical noses or innovative gearboxes, while most teams have restructured internally and the technical staff have been in place from the inception of the new cars' design. Fundamentally, new engine designs from Mercedes, Honda and Asiatech, along with the debut of the Toyota engine, create reliability risks for the teams involved.

Tyres

Michelin

Considering 2001 was Michelin's first season back in Formula One since the 1980s, their performance was amazing, winning four Grands Prix.

Their test programme was initially low key using an old Williams chassis, the development obviously hotted up between the 2000 and 2001 seasons when the teams were able to openly test the new rubber once their agreements with rival tyre company Bridgestone were at an end.

Soon the teams learned that the tyre would suffer a loss in performance due to graining of the tyre's surface after an initial few laps, then the tyre would stabilise and the performance was consistent and didn't suffer degradation as the tyres wore down.

In fact, as the tyres wore down, the grooves would wear thin and the tyres' performance was more akin to a slick (grooveless) tyre. This added performance countered the tyres' natural loss in performance as the chemical grip from the rubber diminished. The resulting tyre led many teams to work out that they could "scrub in" new tyres during practice for 10 or more laps to get them past the graining cycle and then save the tyres for the race, guaranteeing the lasting durable performance.

In several races a set of front tyres lasted the entire Grand Prix, the resulting worn out, almost slick-like tyre lead to protest threats from other non-Michelin teams, as the tyre did not have the full set of grooves demanded by the rules. The FIA only have a loose interpretation of how much groove should remain after a race, and this will no doubt be an increasing issue if the tyres behave as they did in 2001.

The cost of the strong dry weather race tyre Michelin developed for 2001 was a poorer performance in qualifying and a wet weather tyre that was some way behind Bridgestone. For 2002, Michelin accept these failings and have set out to develop new wet weather tyres, with elaborate tread designs being tested especially on the intermediate tyres.

In 2001 Michelin had perhaps only Williams as a top running team - this at a time when Williams were improving their package and by the season's end had clearly joined the top three. This left Michelin at a disadvantage, so for 2002 they have signed with McLaren and now have two undoubted top running teams to develop the tyres and bring in race wins or even a Championship.

Bridgestone

For 2002, Bridgestone were placed in the same position as they had put Goodyear in, back in the 90s. When a new tyre company with an aggressive development plan challenged Goodyear's monopoly in F1, Goodyear withdrew from the sport.

Overall Bridgestone came out on top of the tyre war last year, largely due to the greater performance of their top two teams, Ferrari and McLaren, over Michelin's Williams, but also due to their extra recent knowledge of grooved tyres, the circuits and the behaviour of the modern F1 car. Bridgestone had the data to bring the correct set of tyres to every track. The tyres performed consistently at all tracks in all conditions. Their wet weather tyres were also superior to Michelin's. Only with all the circumstances falling correctly for Williams and Michelin - such as hot weather and a fast track - did the Bridgestone teams fall behind.

McLaren have now switched to Michelin in order to gain a potential advantage over Ferrari. Bridgestone and Ferrari have a close working relationship and McLaren felt that in 2001 they lost out in the direction of tyre development compared to Ferrari. For 2002, the two manufacturers have decided to work even closer, with an entire Ferrari test team dedicated to tyre testing - the resulting development could well be aimed even more at Ferrari's requirements. Other teams are nominated as Bridgestone development partners, but their influence will not compare to the Italian World Champions.

Each tyre manufacturer must bring two nominated specification of tyre for all their teams to each GP. As a result, Bridgestone may adopt a focussed approach to tyre supply and supply a specification tyre more suited to Ferrari, but not to the other teams, who may need to change their cars to extract the potential from the tyres, rather than have tyres developed for them.

Aerodynamics

Last year the FIA made regulation changes to the front wing - raising the height of its outer section whilst allowing the middle section to remain at the old height. At first the teams adopted various approaches, some teams retained flat wings, some teams - like Benetton and Jordan - used complex three-part wings separating each section. Ferrari adopted a so called "spoon wing", where the centre element dips in the centre section to maximise the benefit of the lower height allowed. The spoon wing was adopted by most other teams in some form by the last Grand Prix, and on all the cars launched so far. Only Williams and BAR (with a wing only used once at a test) have retained flatter wings.

The higher front wing also brought problems for other aerodynamic areas of the car: the flow off the higher wing came into closer contact with the underside of the nose and the inside of the wheels. The initial result was to raise the height of the nose of the car - some teams simply made the nose tip higher to allow the wing to work. However, the real issue is the amount of space under the nose all the way back to the sidepods.

This year many teams have raised the entire length of the nose, which is a major exercise to maintain stiffness in the chassis. This then creates a problem that Sauber 2001 designer Sergio Rinland had long understood: if the underside of the chassis is higher than the lower wishbone in the front, the suspension will need somewhere to mount.

Most teams placed a large rib moulded under the nose to mount the wishbone on the car's centre line. This solution is fine, but the large cross section of the rib creates a blockage right where the front wing's flow should go. Furthermore, the long rib extended backward, which in turn creates problems when the car is sliding (yawing), as it presents a larger surface to the airflow creating understeer. Sauber solved this by mounting the lower wishbone on two vertical fins extending from the edges under the nose. These so-called "twin keels" have less frontal and side surface area and result in a more efficient airflow under the car.

With these principles in mind, all teams have looked at the flow under the nose and cleared it up by various interpretations of the single mount's twin keels. Some teams have opted for the extreme solution with twin keels - Arrows extending the keels down to the floor (reference plane) or McLaren's keels angled widely apart to the maximum width allowed.

Another aerodynamic feature seen on many cars are the cooling chimneys and outlets. The heat from the radiators is cooled by air entering the inlet in the front of the sidepods, passing through the ducting and radiators, and then having to exit either through the back of the sidepods or by vents let into the bodywork.

Designers would like to keep the back of the sidepods as narrow as possible, and vents create drag and upset airflow over the car to the rear wing. McLaren's Adrian Newey discovered that if the flow is exited upwards via a tall outlet, then it doesn't upset the flow as much and hence is an efficient way of venting the hot air.

These outlets were soon dubbed "chimneys" and have been adopted by many teams either as a major part of the cooling strategy or as an option to be added for warmer races. Other teams create outlets built into rearward extensions of the sidepods, usually also forming a "flip up" or winglet in front of the rear tyre. While this method is more efficient at cooling, it also has a higher drag penalty.

Ferrari and Jaguar adopted this strategy last year, but for 2002 Ferrari have come up with a new solution, where the exhaust pipe exiting through the top of the sidepod now exits higher and is covered by a small fairing. This fairing acts like a chimney as it is large enough to let some of the heated air escape. The effect of the exhaust pipe in the chimney works like a vacuum pump - the faster jet of exhaust gases pulls air from within the sidepods, effectively sucking the hot air out of the sidepod. This dual use is much more efficient as can be seen by the small cross section of the Ferrari's rear end.

Engines, Gearboxes & Electronics

No major rule changes affect the engine or gearbox for 2002, but the teams have taken advantage of the extra time in the design process to re-engineer these parts nonetheless.

Some teams have followed the 90 degree format, but when Renault made their even wider angle engine, clearly a major trend was initiated. The 2001 Renault engine had a "V" angle over 100 degrees - Renault market it as a 111°, but the actual angle is thought to be slightly less. Either way, this wider angle makes the rear of the car much lower, allowing for a clearer airflow to the rear wing and a lower centre of gravity for good handling.

The downside for the wide angle engine is the excessive width: the narrowness of the "coke bottle" rear end of the car is limited by the wide engine and exhausts pipes, thus creating cooling problems as the designers route the airflow from the radiator through the space now occupied by engine and exhausts.

Furthermore, the low and wide engine is less stiff than the squarer 90 degree engine. The major loss in stiffness is in the vertical plane - the car could literally bend in the middle like a beam. Benetton last year had a lightweight subframe mounted over the engine to replace the stiffness. Other problems with a wide V angle are increased vibration - a bad shape for the airbox. With so many negatives, teams had thought the concept could not be practical in F1. But Benetton and Renault proved them wrong and now all engine manufacturers have gone for a 90 degree or wider V angle.

2002 engine V angles:

Gearboxes

Semi-automatic gearboxes have been common fitment for some time, and the layout and concept of the systems hasn't changed much since. Efficiency has been improved and so has the all important shift speed.

The major development in gearbox technology has come for the construction of the casing. The key aim of the car's designer is to have reduced weight and have that weight placed low. On the one hand, a large, heavy gearbox places a lot of weight quite high and quite far from the middle of the car; on the other hand, lighter gearboxes still have to withstand the suspension and aero loads, plus contain the oil and gears within.

Carbon fibre was adopted briefly as a solution but has fallen out of favour. Cast aluminium or lighter (and more expensive) Magnesium are the popular choice. Additionally, Ferrari had their own direction for a few years, with a mix of carbon fibre sections with a welded titanium centre section housing the gears. Minardi has since pioneered the use of a new technology by Cevolini in Italy, Cast Titanium (Ti), which sees a new process producing complex castings in this high strength material. Now, Ferrari and Toyota have adopted the technology for 2002.

Moreover, Ferrari were rumoured to have cast their engine with the gearbox as one piece. These were only rumours, but Ferrari have adopted new strategies with the placing of the gears, clutch and differential within the casing. Additionally they have found a new way to attach the gearbox to the back of the engine in stiffer manner without compromising serviceability. The exact details of these concepts are still a secret but will become evident over the coming year.

Other technical changes

The high visibility rain light has been increased in size by 50% for the 2002 season, with most teams placing the now rectangular light vertically above the rear crash structure. Benetton (Renault) have always had their light placed like a diamond over the rear crash structure, going back to the design first used during their World Championship years. This styling touch has had to be dropped for the larger light. Ferrari have placed it horizontal making the lower wing element/mount longer above the diffuser for a small aero gain; Arrows seem to have adopted a unique larger rectangular light.

During testing, teams with new cars visibly similar to their 2001 cars could be easily told apart by the size of their wing mirrors - the 50% wider mirrors for 2002 are clearly visible from most angles. On their drivers' request, McLaren have developed strange three part mirrors - each mirror housing has three individual mirrors, each angled differently to provide the driver with three views behind him.

Lastly, new fuel rigs provided by the FIA's supplier Intertechnique will be introduced and have met the teams' demands for more reliable systems, after various failures during races in 2001 to deliver the right amount or any Fuel.

Team by Team

Ferrari

The lack of regulation changes allows a modified 2001 car to take part in a GP, and the gamble Ferrari are playing is that their old car can be on the pace and reliable, while the other teams still learn the set up and experience reliability problems with their new cars. Of course, if one of their major competitors finishes the race ahead of them, then the gamble will not have paid off.

The new car features an all-new rear end which is causing the reliability concerns. The slimmer rear end allows more efficient aerodynamic bodywork, letting the rear wing work in clearer air. The new engine is a development of the old unit and should not raise reliability question marks. And in fact, Michael Schumacher has already said it is more powerful than in 2001.

The front-end of the chassis is another logical development of the 2001 Championship winning car - the team not opting for a twin keel set up but instead a slimmer central one. Ferrari are now the top Bridgestone runner, and having the lion's share of tyre development could be an advantage for the team over their two Michelin-shod rivals. Nonetheless, on some weekends the win might come down to the tyre supplier rather than the team.

McLaren

Furthermore, it is fair to say the car's design was not on a par with recent McLarens, with Coulthard admitting the cars set up was too peaky: when it was set up right, it was fast; when it was not set up right, it struggled.

The new car, however, is a major departure from the old version.

Mercedes have produced an all new wide angle V10 engine and mated it to an all new lighter gearbox. The engine change also affects the aerodynamics, as it requires shorter "periscope" exhausts routing out of the top of the sidepods rather than through the underbody. Adrian Newey has developed an all new chassis around the engine/transmission, and he has also had to take into to account the switch to the new supply of Michelin tyres.

While doing this, Newey adopted a new twin keel front suspension concept, placing the mounts for the lower wishbone on widely spaced fins, under the nose, to improve flow off the front wing. But despite all this change, Ron Dennis insists no risks have been taken, philosophically stating that in order to overtake the opposition when coming from behind, the rules of physics state you need to accelerate and then beat the others. But whether the huge amount of change to the new car and team restructure accelerates McLaren enough, we will discovered in the coming races.

Williams

Visible differences on the new car are hard to detect, but the usual reworking of the nose has been carried without resorting to Sauber type twin keels. The rear end has been lowered, and the bodywork around the rear wheels altered along the line of developments late last year, as has the adoption of periscope exhausts. The BMW engine is all new, but again as an evolution and not a radical new concept. With the team retaining the Michelin tyres for this season, the 'softly softly' approach may make the team's consistency their strong card and bring a Championship home to Williams.

Sauber

For 2002, Sauber receive Ferrari's 2001 rear end, and technical director Willy Rampf has retained the car's main features of the raised nose, spoon wing and twin keel suspension chassis. The sidepods are higher, to accommodate the new engine's cooling requirements. The team have shaved a lot of weight off the car in order to allow more ballast to be run to tune the car's handling and have established a programme to have their own wind tunnel.

Jordan

The new EJ12 has been designed under new technical director and aerodynamicist Eghbal Hamidy, the car is more outwardly dramatic than the previously described cars, with a radical swept nose dubbed the "ant eater". Sauber-type twin keel suspension mounts keep the higher nose free of obstructions, and heavily revised sidepods and cooling outlets continue the search for aerodynamic efficiency. The team now have a supply of the new wider "V" angle Honda engine, and much is made by Honda of the gains for the new unit to counter the criticism last year.

BAR

The new car - the third from designer Malcolm Oastler - is visually similar to the 2001 car, retaining the large sidepods and bulky cockpit area. The car has an "ant eater" nose arrangement, with a central suspension mount and narrower engine cover coming from the new lower Honda engine.

Renault

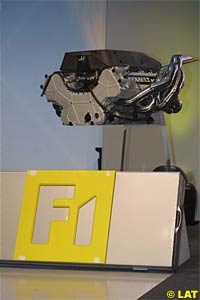

The new Renault R202 car is a clear development of the previous Benetton - the huge amount of detail development carried out throughout the car is not visible, the tidier shape under the nose and detail sidepod changes gives away some of the time spent of on the car. The Renault engine is also developed from the ultimately successful 2001 V10 - Renault being unusually open in displaying the unit for close inspection by journalists at the team's launch last month.

Jaguar

The new R3 for 2002 was completely designed by the team that was in place during 2001. The stability allowed the team to properly address all areas on the car, resulting in a complex car.

The aerodynamics are a major step from the R2 - the raised nose with a unique mix of a central mount for the front of the wishbone and twin keel mounting the rear of the wishbone keeps the underside of the nose very flat. An all new front wing proved a disappointment in testing and resulted in the team going back to establish where the problem occurred in the design phase.

The rear of the car has complex multi link suspension and features a revised Ford Cosworth engine. The car has yet to show its full potential in testing, and questions are now being raised if Jaguar have produced yet another poor car.

Arrows

The new car was largely the work of designer Mike Coughlan, who was joined late in the design process by Sergio Rinland. Rinland's input is clear when looking at the new car: a major reinterpretation of the twin keel front end now has a longer single fin each side to mount the lower wishbone, the fin then extends down to the floor level. The resulting narrow passage between the fins is opened up by the dramatic raising of the nose, the top line of the chassis is horizontal all the way from the cockpit to the nose tip.

Whether this awkward-looking layout is a gain over the simpler design remains to be seen. The rest of the car looks similar to the A22, having only detail changes to the sidepods and engine cover to install the Cosworth engine. This is the other big development for the team in 2002: team principal Tom Walkinshaw secured a deal to have an equal engine supply to that of Jaguar. The cost was excessive and may cause troubles for Arrows in other areas during the season, but the engine is a known quantity and will allow the team's pace to be directly compared to that of Jaguar.

Minardi

The team completed a good season - with the Benetton, Arrows and Prost teams joining them at the rear of the field. By mid season a free supply of the new Asiatech engine was agreed, and the European aviation sponsorship was bolstered by a deal with Alex Yoong and the Malaysian tourist board.

The new car has been in development since the middle of 2001, a more usual period to develop an F1 car. The new engine demanded some changes, and the ability for aerodynamicist Loic Bigois to test in a wind tunnel allowed more adventurous bodywork, resulting in a high nose and more efficient sidepods and cooling arrangements. The team continue to develop the cast titanium gearbox, resulting in a slim rear end for the car.

Toyota

Toyota poached well known designer Gustav Brunner from Minardi, this being the first time he has worked with such a large budget and so many resources. The performance of the test car was berated as being slow, and the team admit they would not be on the pace, but as it was designed to test all the components required for the 2002 season, it was designed to a flexible platform and not as a "race" car.

The new car carries many of the mechanical components proved on the test car and also bears the trademarks of Brunner's design - the neat hot air outlets on the sidepods, the cut outs for the driver's knees in the front of the cockpit, and the cast titanium gearbox. The team do not expect to turn F1 upside down in their first "learning" year but aim to join the top of the grid in a five year plan.

The season ahead should prove to be a more competitive one than even the exciting 2001 Championship. The stability of the FIA's technical regulations and more direct engine manufacturer support means that the teams will be closer together.

During the course of the year, the characteristics of the Michelin tyre became clear. Michelin produced a wider front tyre - the extra width gained from a squarer profile gave the teams more front end grip at the cost of a little extra drag on the straights. Initially the tyres performed well, but were much more competitive in the hotter conditions.

During the course of the year, the characteristics of the Michelin tyre became clear. Michelin produced a wider front tyre - the extra width gained from a squarer profile gave the teams more front end grip at the cost of a little extra drag on the straights. Initially the tyres performed well, but were much more competitive in the hotter conditions.

The trade-off in the flat wing versus the spoon wing is in sensitivity: the lower the wing is to the ground (to a point) the more downforce it creates. This exponential increase in downforce means that a wing nearer the ground makes a larger variation in downforce as the car goes up and down over bumps and during braking, and so forth. This makes the car more sensitive, as the larger variation means less downforce may be made over a lap than with a less sensitive flat wing.

The trade-off in the flat wing versus the spoon wing is in sensitivity: the lower the wing is to the ground (to a point) the more downforce it creates. This exponential increase in downforce means that a wing nearer the ground makes a larger variation in downforce as the car goes up and down over bumps and during braking, and so forth. This makes the car more sensitive, as the larger variation means less downforce may be made over a lap than with a less sensitive flat wing.

The buzz word for engines this year is the V angle, which is the angle between the banks of cylinders on the "V" shaped engine. The original 72 degree angle was favoured for lack of vibration and was narrow enough to keep the rear of the car slim, while allowing space for the designer to put the fuel injection equipment between the banks of cylinders. Ferrari then moved to a 90 degree angle, and while the engine was wider, it was also lower - an increased consideration, since the car's wheelbase was made narrower in the late Nineties.

The buzz word for engines this year is the V angle, which is the angle between the banks of cylinders on the "V" shaped engine. The original 72 degree angle was favoured for lack of vibration and was narrow enough to keep the rear of the car slim, while allowing space for the designer to put the fuel injection equipment between the banks of cylinders. Ferrari then moved to a 90 degree angle, and while the engine was wider, it was also lower - an increased consideration, since the car's wheelbase was made narrower in the late Nineties.

With just two weeks to go before the Australian Grand Prix, Ferrari have announced they were to run the older F2001 at Melbourne, as they felt they had not completed enough testing to be certain of the reliability of the new F2002.

With just two weeks to go before the Australian Grand Prix, Ferrari have announced they were to run the older F2001 at Melbourne, as they felt they had not completed enough testing to be certain of the reliability of the new F2002.

The team had a disappointing season despite second place in both Championships. Mika Hakkinen's decline in motivation and designer Adrian Newey's attempted move to Jaguar both affected the team's concentration, while the Mercedes engine lost out in performance, as they developed replacement metals for the banned material beryllium.

The team had a disappointing season despite second place in both Championships. Mika Hakkinen's decline in motivation and designer Adrian Newey's attempted move to Jaguar both affected the team's concentration, while the Mercedes engine lost out in performance, as they developed replacement metals for the banned material beryllium.

With four wins in 2001, Williams are again in the ascendancy, now going into the third year of their partnership with BMW. The team have arguably the best engine, the best driver pairing and the most experienced technical head. The car in 2001 was disadvantaged aerodynamically on slower high downforce circuits, but this shortcoming has been addressed by designer Gavin Fisher on the new car, despite the cars' outwardly similar appearance.

With four wins in 2001, Williams are again in the ascendancy, now going into the third year of their partnership with BMW. The team have arguably the best engine, the best driver pairing and the most experienced technical head. The car in 2001 was disadvantaged aerodynamically on slower high downforce circuits, but this shortcoming has been addressed by designer Gavin Fisher on the new car, despite the cars' outwardly similar appearance.

The Swiss-based team enjoyed their strongest season to date, despite sponsorship and ownership wrangles and the departure of designer Sergio Rinland before the 2001 season started. Although Sauber have had a supply of Ferrari engines previously, they were previously developed and maintained by Petronas under the direction of Ex Honda and Ferrari engine man Osamu Goto. For 2001 the engines were maintained by Ferrari and came with the full transmission package along with electronics and technical support. Hence, with a known rear end, the team developed a neat chassis around it, the car performed well all season and enjoyed continued development throughout the season - previously Sauber's weak point.

The Swiss-based team enjoyed their strongest season to date, despite sponsorship and ownership wrangles and the departure of designer Sergio Rinland before the 2001 season started. Although Sauber have had a supply of Ferrari engines previously, they were previously developed and maintained by Petronas under the direction of Ex Honda and Ferrari engine man Osamu Goto. For 2001 the engines were maintained by Ferrari and came with the full transmission package along with electronics and technical support. Hence, with a known rear end, the team developed a neat chassis around it, the car performed well all season and enjoyed continued development throughout the season - previously Sauber's weak point.

2001 was a second successive year without good results for the Jordan Grand Prix team. With a full Honda engine, the team probably expected more performance from the engine, but equally the chassis lacked pace even if it was well balanced.

2001 was a second successive year without good results for the Jordan Grand Prix team. With a full Honda engine, the team probably expected more performance from the engine, but equally the chassis lacked pace even if it was well balanced.

BAR's previous cars have lacked pace and have been unreliable - 2001 brought a car reluctant to respond to set up changes and responding inconsistently when it did. The impossible problem brought a closer relationship to Honda, who helped develop new parts for the team. This relationship was cemented with the signing of a three year partnership between the companies. Honda will provide technical support beyond the engine, covering vehicle dynamics, gearbox and aerodynamics, while Jordan will only receive engine support.

BAR's previous cars have lacked pace and have been unreliable - 2001 brought a car reluctant to respond to set up changes and responding inconsistently when it did. The impossible problem brought a closer relationship to Honda, who helped develop new parts for the team. This relationship was cemented with the signing of a three year partnership between the companies. Honda will provide technical support beyond the engine, covering vehicle dynamics, gearbox and aerodynamics, while Jordan will only receive engine support.

2002 will be the first year the French manufacturer's name will headline a team since the 80's, after their quieter involvement with Benetton in 2001. Just as well, considering the poor state the Benetton team were in for the start of the season, with an engine and chassis that didn't work. However, the team worked well together and produced a fine car by the season's end.

2002 will be the first year the French manufacturer's name will headline a team since the 80's, after their quieter involvement with Benetton in 2001. Just as well, considering the poor state the Benetton team were in for the start of the season, with an engine and chassis that didn't work. However, the team worked well together and produced a fine car by the season's end.

The Jaguar car for 2001 was over conservative and major updates were rushed in under the new technical management that joined the team last year, to rectify its faults. The team, however, never fully caught up this loss of pace, but the Michelin tyres and hard race driving brought some strong race performances that frequently ended by accidents or reliability problems.

The Jaguar car for 2001 was over conservative and major updates were rushed in under the new technical management that joined the team last year, to rectify its faults. The team, however, never fully caught up this loss of pace, but the Michelin tyres and hard race driving brought some strong race performances that frequently ended by accidents or reliability problems.

Arrows effectively limited their potential in the 2001 Championship when they drew the new car: it was designed with a low drag aerodynamic set up and a small fuel tank. This worked commercially, getting the team to the top of the speed trap figures despite one of the poorer engines in F1. Moreover, they had to run very light on fuel in the race and produced sometimes startling performance in the first stint in the race, before dropping out of contention as they had to pit stop an extra time.

Arrows effectively limited their potential in the 2001 Championship when they drew the new car: it was designed with a low drag aerodynamic set up and a small fuel tank. This worked commercially, getting the team to the top of the speed trap figures despite one of the poorer engines in F1. Moreover, they had to run very light on fuel in the race and produced sometimes startling performance in the first stint in the race, before dropping out of contention as they had to pit stop an extra time.

Yet again no reward for the small Italian team in 2001, but the major prize was survival. Back then, with only a month until the season's start and the collapse of the Supertec engine deal, Minardi fell back on the dated Fondmetal-tuned Ford engine, and designer Gustav Brunner completed the design and construction of the car in a matter of weeks, with no reference to a wind tunnel or time for a failed crash test.

Yet again no reward for the small Italian team in 2001, but the major prize was survival. Back then, with only a month until the season's start and the collapse of the Supertec engine deal, Minardi fell back on the dated Fondmetal-tuned Ford engine, and designer Gustav Brunner completed the design and construction of the car in a matter of weeks, with no reference to a wind tunnel or time for a failed crash test.

New to Formula One and already boasting a huge budget and year of testing at the major circuits, the German based team have created a complete F1 car, including engine, from scratch. The aim of the operation is to produce everything in a single factory, to get the most from the integration of the components. Only Ferrari do F1 this way - Renault approach it, but the engine and chassis factories are in separate countries.

New to Formula One and already boasting a huge budget and year of testing at the major circuits, the German based team have created a complete F1 car, including engine, from scratch. The aim of the operation is to produce everything in a single factory, to get the most from the integration of the components. Only Ferrari do F1 this way - Renault approach it, but the engine and chassis factories are in separate countries.

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 8, Issue 8

2002 Season Preview

2002 Drivers Preview

2002 Teams Preview

2002 Technical Preview

Men and Motors

Articles

The FIA's Court of Appeal: Part IV

Off-Season Strokes

Columns

Elsewhere in Racing

The Weekly Grapevine

> Homepage |