Atlas F1 Technical Writer

Renault have one clear goal for the 2005 season: win races and fight for the both titles. To achieve their goals they have put all their efforts into the new R25. Atlas F1's Technical Writer Craig Scarborough had the chance to see the new car during its first test and talk to its designers about some of the new features

Last Year

One of the factors often cited last year for the teams' superb traction and race starts was a deliberate policy to create a rearwards weight bias. While the team admit there was a rear weight bias, this was an unavoidable result of the late starting engine project. In fact, the team's starts are more accurately attributed to their approach to the engine and clutch control at the races start. The teams' knowledge of the physics of the launch process was reflected in their control systems and the cars often started quicker than everyone else.

This Year

Renault revolved their design teams once more with Tim Densham designing the new car over the two-year gestation period for its matching engine. Technical director (chassis) Bob Bell heads the team in the UK, while Rob White directs the engine department in France. The teams' often oblique approach to problem solving has found yet more innovative solutions to problems other teams approach head on. The early starting chassis program was not compromised by the late announced rules, as the initial work covered more than simply the aero which changes for 2005.

Aerodynamics

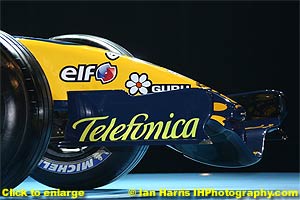

Renault's front wing follows what will probably be the standard shape front wing for 2005, in that the middle section is curved downwards and the outer tips flicked up slightly; the wing has a long chord and a lot of camber through out its span. As it has been raised Bell said the wings outer spans no longer gain from ground effect, but that is offset by less pitch and roll sensitivity. But the compromise on setting the middle section so low is "it brings you a bit more performance at the expense of a bit more sensitivity", the resulting pressure distribution across the wing is now "is quite different". It has been matched to endplates seen late last year, with slight cutouts on the leading edge just below the main plane.

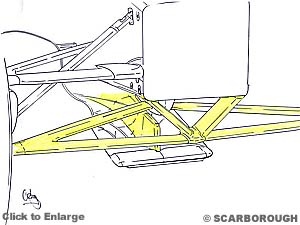

It's where the flow from the front wings goes that Renault have centred the attention. While the height of the chassis and front bulkhead remain fixed, the keel area features an innovation not seen before. While normal single keels feature a central wishbone mount with the keel rising and widening to meet the monocoque, Renault have split the keel into a "V" with two mounts on the monocoque and the single central pick up, the rear legs of the lower wishbone mount on a single stubby keel further back along the nose.

As Renault's previous rib-like keel running under the length of the nose is not there to split the flow over the shadow plate, the shadow plate now features a tall thick fence to split the flow and merge it into the sidepods' leading edge, also providing a neat and low location to house ballast. The whole shadow plate is double skinned and suggests the level of weight loss Renault have been able to achieve this year.

On both sides of the shadow plate simpler bargeboards shape the flow around the sidepods, along with slightly more sculpted sidepod fronts. The "Axe-Head" fins fitted to the rear end of the bargeboards are now more aggressive with a tall gurney on their outer edges, as is the piece of bodywork bridging the main floor with the bargeboard, both gurneys acting to flick flow up from under the floor and preventing it upsetting the diffuser.

Within the sidepods the radiators are no longer book folded and are instead flat with shaped end tanks to clear the sidepod sculpting. Evacuating the heated air from the sidepods is again a feature of the Renault, an optional chimney first vents the flow, then heavily louvered grills over the exhaust area continue to cool the sidepods.

Matched to the chimney are new winglets, which are now mounted on a small strut which passes its loads back into the engine cover in an area not filled with louvers.

Exhaust outlets are now at the most narrowest part of the sidepod and do not even protrude from the top deck. Flip ups of a typical design flank the sidepods with the vertical section between the wheels not yet carrying a shelf wing. The roll structure does however carry a narrow mid wing. Again, the rear wing follows a typical Renault design with the integrated flap and endplate arrangement for managing vortices, then the endplate also takes the load from the upper wing to the lower beam and into the chassis.

The diffuser keeps the outer sections of the floor flat and adopts a steep initial slope to the outer channels, this steep initial slope starts with a step between the floor and diffuser. When asked if this had any intrinsic problem with sensitivity, Bell said: "If you design something that's right on the limit at one attitude of the car and then is goes to a slightly different attitude then it stalls, that would cause some horrendous problems, bit I think we are all cleverer than that . With square exits and as yet no extra gurney flaps above the exits."

Engine and Mechanicals

For 2004 the team decided to abandon the wide angle concept in the light of the one engine per weekend rules. They instead followed a 72-degree V angle that the team were already familiar with. The engine development was compressed in order to make its debut for Melbourne 2004. As a result the engine was overweight and this unduly affected the car's weight distribution. For this year the team started their development with more reasonable timescales, but the project under Axell Plasses' management also needed to cope with the double engine life rules.

The resulting engine is all new and still features the narrow 72-degree angle. Its weight is still of the same order as the RS24 from last year, while engine speed and power output are up. The engine mates to a new six-speed gearbox, made in Cast Titanium, which has had major updates to improve it over last year's unit to recover losses from the clutch control solution banned under the new rules.

Elsewhere around the chassis, weight has been taken out of the structures to allow a very thick shadow plate with plenty of space to restore the underweight car back to the minimum weight. For the benefit of centre of gravity, the team didn't feel the rearward weight bias implied by the heavier engine would be completely overturned.

"We're never satisfied that have too much moveable ballast, we will constantly strive to take weight out of chassis and engine to give us more flexibility, but there's no bottom limit," Plasses said.

In the team's short life as Renault, innovation has both allowed them to catch up with the opposition and been their downfall. With the engine architecture moving from radically wide to unfashionably narrow the motor's performance had let down the chassis and electronics. Going into the second year of Bob Bell and Rob White's direction the team are catching up on the engine front and again innovating on the chassis.

Inherently Renault produced a good car last year. The problems the team had were to do with low engine outputs and sensitive handling. The rush to get the new narrow angle engine out in time hindered its potential output and weight. While the sensitive aerodynamics saw the car being difficult to get working on either side of the knife edge of balance\grip. This handling deficiency upset the tyres and eventually one of the teams' drivers.

Inherently Renault produced a good car last year. The problems the team had were to do with low engine outputs and sensitive handling. The rush to get the new narrow angle engine out in time hindered its potential output and weight. While the sensitive aerodynamics saw the car being difficult to get working on either side of the knife edge of balance\grip. This handling deficiency upset the tyres and eventually one of the teams' drivers.

Starting at the front, Renault have kept the nose tip high and slim, Bob Bell confirmed this was for aerodynamic advantages, commenting the more commonly drooped nose does provide some interaction with the front wing, which can give some improved balance, but as the Renault chassis was already well balanced they did not need this feature. He also said it did not cause any problems with the increased impact tests this year: "We had no problems with the frontal impact tests this year, we usually have a couple of goes at it, to be absolutely sure we got it right". The raised nose starts a sequence of new developments aimed at improving flow under the car, Bell said the fundamental aims for this: "Ultimately most of the aero performance comes from what you do at the back of the car, but is strongly influenced what you do at the front of the car. The cause is at the front and the effect is at the back. We worked very hard to optimise the front aero to make sure the back works."

Starting at the front, Renault have kept the nose tip high and slim, Bob Bell confirmed this was for aerodynamic advantages, commenting the more commonly drooped nose does provide some interaction with the front wing, which can give some improved balance, but as the Renault chassis was already well balanced they did not need this feature. He also said it did not cause any problems with the increased impact tests this year: "We had no problems with the frontal impact tests this year, we usually have a couple of goes at it, to be absolutely sure we got it right". The raised nose starts a sequence of new developments aimed at improving flow under the car, Bell said the fundamental aims for this: "Ultimately most of the aero performance comes from what you do at the back of the car, but is strongly influenced what you do at the front of the car. The cause is at the front and the effect is at the back. We worked very hard to optimise the front aero to make sure the back works."

Bell shrugged the design off as simply an "elegant bracket". He confirmed that as the solution is "lighter and more aerodynamically efficient solution" plus as its triangulated it is "more structurally efficient". It appears the solution is aimed at retaining the better suspension geometry of a single keel, while opening up the under nose area to improve aerodynamics (as with a twin keel). As the end result is lighter as well this solution appears to win on all sides.

Bell shrugged the design off as simply an "elegant bracket". He confirmed that as the solution is "lighter and more aerodynamically efficient solution" plus as its triangulated it is "more structurally efficient". It appears the solution is aimed at retaining the better suspension geometry of a single keel, while opening up the under nose area to improve aerodynamics (as with a twin keel). As the end result is lighter as well this solution appears to win on all sides.

Bell clarified why these were used over a open duct: "It's a way of diffusing the exit air from the radiators systems benignly into the external airflow, the more gently you can do that the less disturbance you create for what sitting behind it all", but sending the louvers exit flow straight towards the rear wing has its problems "when you go to very extreme requirements for cooling you can accept higher performance degradation of what sits on the car behind it. We can open it more and more of it up and as progressively the cooling becomes more in hand we can progressively close them off and further improve the quality of the flow".

Bell clarified why these were used over a open duct: "It's a way of diffusing the exit air from the radiators systems benignly into the external airflow, the more gently you can do that the less disturbance you create for what sitting behind it all", but sending the louvers exit flow straight towards the rear wing has its problems "when you go to very extreme requirements for cooling you can accept higher performance degradation of what sits on the car behind it. We can open it more and more of it up and as progressively the cooling becomes more in hand we can progressively close them off and further improve the quality of the flow".

As its effect is to pull air from under the floor, it could be likened to as a gurney, but Bell said "It's not as crude as a gurney, a gurney does involve a lot of separated flow the initial ramp in the diffuser doesn't."

As its effect is to pull air from under the floor, it could be likened to as a gurney, but Bell said "It's not as crude as a gurney, a gurney does involve a lot of separated flow the initial ramp in the diffuser doesn't."

The electronic control systems that would otherwise be separated between chassis and engine have been mated to an all new Magnetti Marrelli Step11 control unit. Having all these systems out of one ECU has some advantages in passing one parameter from the chassis to the engine, which was possible before but "with one integrated system allows you to do it faster," according to Plasses.

The electronic control systems that would otherwise be separated between chassis and engine have been mated to an all new Magnetti Marrelli Step11 control unit. Having all these systems out of one ECU has some advantages in passing one parameter from the chassis to the engine, which was possible before but "with one integrated system allows you to do it faster," according to Plasses.

|

Contact the Author Contact the Editor |

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 11, Issue 5

Articles

A Day in the Life

Technical Analysis: Williams FW27

Technical Analysis: Renault R25

Regular Columns

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |