Atlas F1 Technical Writer

Sauber had an impressive and promising finish to the 2004 season, with a new state of the art wind tunnel proving a worthy investment for the Swiss team. Atlas F1's Craig Scarborough spoke to the team's chief designer Willi Rampf about the team's efficiency and progress in 2004

In reality, the car was mechanically from the engine backwards a Ferrari, but the other mechanical, suspension and aerodynamics were in fact the work of the team in Switzerland. Hence, the result of these investigations saw alternatives to their established design concepts discarded for new well research ones.

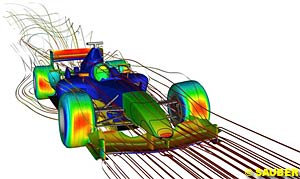

The switch from twin to single keel allowed the team to shed weight from the chassis to be put into centre-of-gravity lowering ballast, and the original sidepod arrangement was more a part of the engine packaging than the aero. As their new wind tunnel and Computational Fluid Dynamics (CFD) programmes blossomed in the early season, new parts appeared on the car, including the dramatic folded radiators and later the shrunken engine cover. Although perhaps stymied by their Bridgestone tyre supply, the cars were flying by the season's end, as demonstrated by both drivers in the last few races.

Wind Tunnels

CS: Going all the way back to 2003, where did the team expand the aerodynamic work into another wind tunnel (from their main tunnel in Emmen)?

CS: Why was it decided to go to another tunnel?

Rampf: "Because in Emmen we could only book certain amounts (of time), so we filled in where we could by booking Lola."

CS: During this time, you were developing the new Sauber wind tunnel. What tunnel was the new, 2004 car developed in?

Rampf: "The concept of work on the current car was done in Emmen."

CS: What are the technical details of the new tunnel?

Rampf: "We run a 60% model and a belt speed of up to 80ms. We can go even above 80ms, but this is the maximum speed we are running now. We can yaw the car, roll the car, pitch the car and steer the front wheels."

CS: Do you blow the exhausts?

Rampf: "Yes, we do from time to time. This is done from time to time just to make sure we do not overlook something."

CS: How many attitudes do you try in a tunnel run?

CS: This work is balanced with the CFD work. How is the CFD programme producing parts to go into the wind tunnel?

Rampf: "CFD is supporting the aerodynamic work in the tunnel, so if there are some areas which need to be explored more in detail then we do it in CFD. If we develop a new radiator duct, we can do a lot of it with CFD work, long before we see the first model parts. If you take the front wing, you can almost do a complete front wing in CFD – it's much more accurate. But it's much more difficult to optimise a diffuser because it's at the rear of the car and you need a lot more calculations."

CS: How does the CFD work correlate to the windtunnel results?

Rampf: "From the wind tunnel to CFD, what we do from time to time are calibration runs. We, for example, measure the pressure distribution of the front wing; we compare the measurements to the CFD data most of the time there is good correlation."

Rampf: "There will always be a difference between tunnel and track. In the tunnel, you run a carbon fibre tyre; in reality, on a track, you run a tyre with a different contact patch which has an influence on the measurements. There are always some corrections to the data."

New Car

CS: It was rumoured that the car's aerodynamic surfaces are a copy of the Ferrari. Was there any input from Ferrari on this?

Rampf: "No, there was the normal input on engine and gearbox. We bought the gearbox from Ferrari, but all the chassis, suspension, etc. was all done here at Sauber; designed and manufactured; everything."

CS: Were the folded radiators part of the original concept? They were not completely ready until Monaco

CS: Did it give more radiator surface area, or was it for packaging?

Rampf: "No, it was packaging. The radiator area, when you define it, is the amount of cooling you need, so it just gave us a better package."

CS: The new engine cover at Silverstone was one of the most dramatic on the grid. What were the aims behind the change?

Rampf: "We tried to basically to have a very low engine cover to get a better flow to the rear wing."

CS: Did it work better at all attitudes?

Rampf: "Yes, it worked quite well."

Tyres

CS: In second qualifying and the races, you ran a lot of fuel. Was that due to race tyre performance?

CS: You seemed to suffer a lot of graining, especially on the rears. Was this a result of lack of downforce or aero efficiency?

Rampf: "We had situations where the rear tyres were degrading; for sure the low engine cover helped here, more downforce makes less tyre degradation."

CS: Felipe Massa developed a reputation for not being kind to tyres, is that true?

Rampf: "No, Felipe learned a lot during this season, it would be wrong to say he is very hard on tyres. We also tried sometimes different tyre specifications; one driver soft, one driver hard. Maybe it looked from the outside that he was hard on tyres, but may be it was a different spec tyre."

Engines

CS: You had three engine failures in practice and one in a race. Were the problems on the engine's internals or its installation?

Rampf: "They were not installation related..."

CS: That must be disappointing, after Ferrari's reliability record?

Rampf: "that's right."

CS: were any of the failures related?

Rampf: "No."

Sauber have been a staunchly independent mid field team for many years. Often with the advantage of factory backed engines, their supply of Ferrari engines has had the rumour mill exaggerating the technical interchange between the companies. Heading the teams design department since 2000, German Willi Rampf is now directing the team's development on the new 2005 car. Last week, he took a break to speak exclusively to Atlas F1.

In 2003, Sauber had a bad year with the car not performing well, until late in the year a major step in the aerodynamics brought them back up to speed. They were developing a state of the art wind tunnel and for 2004 they had purchased a supply of Ferrari gearboxes. When the new car was released, the striking similarity to the F2003-GA was uncanny; such was the car's departures from previous Sauber values.

In 2003, Sauber had a bad year with the car not performing well, until late in the year a major step in the aerodynamics brought them back up to speed. They were developing a state of the art wind tunnel and for 2004 they had purchased a supply of Ferrari gearboxes. When the new car was released, the striking similarity to the F2003-GA was uncanny; such was the car's departures from previous Sauber values.

Rampf: "This work was done in the Lola windtunnel. This work was done partly at Lola and partly at Emmen."

Rampf: "This work was done in the Lola windtunnel. This work was done partly at Lola and partly at Emmen."

Rampf: "We run a map; we are not simulating all yaw angles, ride heights and steering angles. You simulate characteristic situations, for example straight-line, straight-line braking or corners. Not, for example, steering the front wheels with no roll angle because this doesn't happen in reality. We are concentrating on situations proven in normal driving; cornering and straight-line braking."

Rampf: "We run a map; we are not simulating all yaw angles, ride heights and steering angles. You simulate characteristic situations, for example straight-line, straight-line braking or corners. Not, for example, steering the front wheels with no roll angle because this doesn't happen in reality. We are concentrating on situations proven in normal driving; cornering and straight-line braking."

CS: And the correlation from wind tunnel results to the track?

CS: And the correlation from wind tunnel results to the track?

Rampf: "When we started the season, we had them on one side and then we introduced this later in Monaco for both sides - oil and water. It was basically the first step to go to the very low engine cover."

Rampf: "When we started the season, we had them on one side and then we introduced this later in Monaco for both sides - oil and water. It was basically the first step to go to the very low engine cover."

Rampf: "Yes, exactly. It was the best we could do as the tyre was very consistent in race conditions, so if you don't start from the first two rows it was better for us to stay out longer."

Rampf: "Yes, exactly. It was the best we could do as the tyre was very consistent in race conditions, so if you don't start from the first two rows it was better for us to stay out longer."

|

Contact the Author Contact the Editor |

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 10, Issue 51

The Season of the Struggle

The Phantom of Fiorano

Tech Talk with Sauber's Willi Rampf

2004 Testing SuperStats

Bookworm Critique

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |