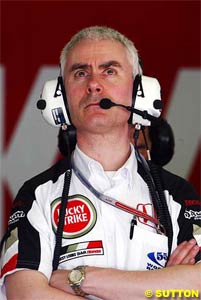

Interview with Geoff Willis

Atlas F1 GP Editor

Jenson Button's maiden podium at the Malaysian Grand Prix last week was the first sign that BAR are coming of age. The team are now in the same position as Renault were last year: the young upstarts that want to shake up the previous order and prove their worth. "We're going to be very cautious," Geoff Willis noted after Button's third place finish. "Where we are trying to compete now there are some very, very strong teams, and I have no intention of underestimating how strong they're going to be." David Cameron quizzed the drivers and leaders of the team from Brackley about the improvements they've made and where do they go from here. Exclusive for Atlas F1

During this period he became heavily involved in the emerging black art known as Computational Fluid Dynamics (CFD), a process that was to revolutionise aerodynamic design in Formula One. Willis joined the Leyton House team, the first CFD engineer in the sport, before moving to Williams, moving up the ranks of the design team to work along side Adrian Newey and Patrick Head.

In 1997 Willis was appointed to the position of Chief Aerodynamicist following the departure of Newey to McLaren, and he worked with Chief Designer Gavin Fisher on the team's car design until Willis was offered the role of Technical Director at BAR. He joined the team at the start of 2002 and started the process of rebuilding the technical team."

DC: There has been a clear improvement in the team towards the end of last year, over winter testing and this year, although obviously the process goes back a lot further. Where would you put the start of that process?

Geoff Willis: "Well it was fortunate and coincidental that David Richards started here just before I did; he started at the beginning of the year I think, and I started in early March; and so almost everything had changed. The whole management structure of the team had changed, the technical structure of the team changed, and he really kind of took everything apart and put everything back together again in the first few months.

So the big change was the things we did in March, April and May 2002; then we slowly built up the design team and all the rest of the operational team, manufacturing, sorting a number of processes out, management of how we do things internally, fixed some of the problems we had with the 2002 car and mainly focused on the 2003 car, got a whole load of engineering quality level up and put ourselves in a position where we could focus on a proper, high technology, front end of the grid car for 2004.

DC: What did you identify as the major problems coming into the role?

GW: "The management structure, how the team was run technically, was not very efficient. There was lots of confusion over roles, responsibility and authority; it wasn't clear what people were supposed to be doing on the key things that needed to be done. And so we targeted a number of different areas in the quality of manufacturing and design, and really improved the whole quality of design I think; that was the biggest thing we did.

"And we got to a point where our safety, testing and process controls were so much stronger that every car was the same, so if we had a problem it could be fixed quickly and addressed quickly; there were systems to control faults and problems and a proper structure for the 2003 car. High quality design, things were made well, everything passed all the FIA tests first time, we test everything accurately, and life everything, control it, and have a safe, reliable car that doesn't break often."

DC: I'm assuming there were two major areas; the budgetary and the technical; and while the budgetary issues may have been out of your control, the technical issues...

DC: And it's a slow process.

GW: "It is. We had quite a large change made to the technical staff of the team, and that took quite a while to get the right people and build the right structure. We had a few goes at it; our first go at it wasn't perfect, and we had a few steps evolving how the structure works and how the different areas work, where the responsibilities were, and once you get it to start to work you can look at where the problems are and fix those, and have the next step."

DC: I say it was a long process, and you came fifth last year but really before the last race it was so close between a number of teams...

GW: "We certainly let ourselves down with reliability problems a lot last year, and they were all remarkably trivial but still stopped the car; some sensor failures, a connector failure, the brake balance pipe - never seen the problem before and then suddenly saw a rash of them - and a couple of wiring problems that caused fires. And when you went through it you found that we didn't really have the processes right all throughout the factory.

"And also there were far too many changes coming from Honda; Honda were pushing very hard, and there was almost a new engine spec at every race, and we just weren't able to do our testing and racing in sync, so we were always sort of testing new things at races, which is not the right thing to do. So it was all just about trying almost too hard, more than the team could do."

DC: It seemed in the past that there was almost two teams, that there was BAR and there was Honda, but the two sides seem a lot closer now.

GW: "It is a lot closer. I think the first step is to get mutual respect, both on a technical and a business side, and I think it took some while to pull the Honda engineers and the BAR engineers together and to realise that, yes, they have strong areas and they have weak areas, that there are some things that we can get good advice from Honda and some areas where they can benefit from our experience.

"It's a gradual process, but I think you're right in saying that you don't really see much to start with; when you're laying all the foundations down it looks like you don't see much construction at all; you can't see anything above the ground, but you spend a good eighteen months doing it and then suddenly you start to see that now the car has components that are of a much, much higher quality than before. We have a very neat car and good gains in the windtunnel; and this is all because the foundations were put together properly."

DC: Honda have suggested for some time that they want to be involved not only in the engine development side but also in the car development; Sato suggested that they are becoming involved in the suspension geometry and other areas.

"I think all the car manufacturers are very interested in seeing what they can get from their car engineering side, but the problem is that Formula One has pretty little to do with road cars; the technology is all aerospace, and is almost not automotive at all; so I think it takes a little time for engineers from the automotive world to work out where they can add, and what we've been trying to do is make sure we're using the extra resources in a properly structured, programmed way."

DC: In a way then it seems that it's not so much that Honda is assisting the chassis programme, but rather that you are letting them come in and showing them how to go about it.

GW: "Yes, but really their engineers are actually involved in our teams that do the designs. The overall concept and layout of the car is 100% BAR, but we discuss what we're doing with Honda; we discuss the engine installation, we discuss gearbox concepts.

"Honda have gone away with a BAR gearbox concept a while ago and refined the design, and now Honda have both designed and manufactured the gearbox internals; the gearbox main case, the carbon concept main case, is 100% BAR but the internals are a sort of BAR Honda concept, Honda designed, Honda manufactured, so there's a way that you can get a good crossover from the technologies that Honda have and the experience and expertise that BAR have.

"Similarly Honda have been running a windtunnel programme for some time on Formula One cars, and we've pulled some of their aerodynamicists on to our own windtunnel programme, and they've been working on some concept rear wings that you'll see later in the year which are Honda concepts and again refined by the team.

"So it's sort of feeding ideas, feeding resources in; obviously Honda's a big company and has huge resources and a lot of people who can all service specific problems, and so as we develop the car we start to look at smaller problems in greater detail, and we can pull in the resources of Honda."

DC: So this is just the process that the relationship is going to go through, going forward?

GW: "I think so. We're a company of 425 people, and we're trying to compete against companies with another hundred people on top of that, so we've just got to use the extra resource."

DC: There was a process a little while ago of bringing more and more engineers into the top teams, and just throwing live bodies at a problem. Is that process still ongoing, or have the teams arrived at about their natural levels?

GW: "It's a difficult question, because the bigger your design groups get, your Research & Development groups get, the more effort you have to put into managing them. So you get quite a large amount of your time taken up with just managing people, and it's quite a technically tricky process managing big projects with lots of engineers. And I think if you don't have your management structures correct then if you just add more resource eventually your specific efficiency keeps dropping; you may have doubled your resource but you've got scarcely ten percent more results from doing it.

"There is a specific amount in, say, windtunnel testing where the more testing, the more parts you put through the windtunnel, the faster your progress is. But you get to this law of diminishing returns and at some point you have to say no, we need to be clever and work hard, but we need to be much more efficient. So we've been focusing very much at how we can be more efficient in engineering design."

DC: How do you manage engineering design? Engineers have a tendency to focus in on their one specific task without perhaps looking at the bigger picture of where their area fits in...

"So we certainly believe in very strong management, and that's what we've been putting a lot effort into; getting management training for our engineers, because a lot of people think it's a bit creative, and I can't plan creativity, I don't know when I'm going to make the car half a second faster. Well, if you don't have a plan you just use up resource without any results. So we've been quite strong in putting a lot more detailed plans together, the car is designed to plan, manufactured to plan, it's operated to plan, and we are getting more and more structured in the way we operate."

DC: I suspect that a lot of this has come from your background at Williams, where they presumably have been operating in this fashion for some time.

GW: "I don't how Williams is operating now, but I'd say that BAR is a lot more structured than how Williams is. Obviously the team hasn't been operating together for anywhere near as long as Williams has, and Williams has a lot people who have, and I mean this in a good way, covered each other's backs for twenty years.

"And by that I mean that you know that when you are designing a new car you're not going to forget anything because everybody knows each other's strengths and weaknesses, so you remember that the guy who has to remember where the water bleeds goes is going to remember to do it; it's easy to drop these things off (smiles).

"But in terms of pure technical skill I have no worries that we at BAR can compete easily, certainly with my old team, in terms of composites and mechanical design, aerodynamic design; I believe we're very strong. It's just that we're learning, we're going up step by step, and this is year three of a five year plan. At the moment we're on plan, but it's going to be a tough year; as you can see there are five very tough teams at the moment, with us in there, and we want to kick at least one of them out of the way."

DC: Looking at the improvement at BAR is similar to looking at an iceberg; most of the work has been below the surface, and we're now starting to see something pop up above. What do you think has been behind this recent, noticeable improvement?

GW: "Specifically technically with this year's car we've made some fairly substantial weight savings, particularly at the back of the car; carbon composite gearbox, new light weight internals, new engine, light weight suspension, rear and back structural, the centre of gravity is very much lower than last year, and a lighter smaller engine with the same sort of power as end of last year. And we made a big step in aerodynamics, both in absolute downforce figures and also the characteristics, where the car is strong in a variety of ride heights and attitudes. So that's what has made the car a lot stronger."

DC: It's a remarkably clean looking car, which presumably was intended.

GW: "It is; it's a sort of ... I don't know if there is a BAR style yet, but we're trying to make everything as simply, neatly and cleanly as possible. Unfortunately with the form of Formula One aerodynamics at the moment you do tend to see a profusion of sort of widgets on the cars; we've kept away from them at the moment while we had some problems in recent years with inconsistent repeats in the tunnel and the track.

"So we decided to simplify the car, and get into a position where we really understand the car, so that it exactly ties in with what we see in the windtunnel, and then you get a lot more confidence in your windtunnel programme. And then you find that when you gain two percent in the tunnel you can make the part and just bolt it on, give it a quick test to make sure it doesn't give any problems to other parts of the car, and then that becomes the race spec."

DC: Can you actually find two percent these days?

GW: "Yep; we've got another two or three percent coming on the car shortly. It's relentless; we have to find any air, somewhere between six and eight percent. Six percent keeps you roughly equal with the rest of the pitlane, and eight percent gives you a little step forward. I certainly think Ferrari have found eight percent or so."

DC: How do you think they've found that?

GW: "Little bit difficult; we're having a careful stare at it because it's not obvious where it's happened. I think they've made a big aerodynamic improvement, and now we have to understand what they've done and do the same ourselves."

DC: Does the simplicity of the car lend itself to being a stable base to then work on for the various requirements of the different races?

GW: "Well it's simple in shape, but it's quite sophisticated underneath. As I say we've got, particularly in mechanical and composites systems, some very neat engineering there, so I think it's just a smooth, simple shape aerodynamically. There are some quite subtle bits on there now, some very small details on there that are making some differences.

"And obviously we've changed the tyres recently, and that's got a new unknown in our tunnel programme because the tyres are a different shape and a different weight, and they need a different set up on the car, so we're learning quite a lot anyway. I think we'll be in a position to make some reasonably big changes this year."

DC: How long will it take the team to adapt to the tyres?

GW: "It will probably take us most of the season; I think we're up to about 85% of the way, and we had quite a steep learning curve and worked very well with the Michelin engineers. I think we've got a lot of the way there but, for instance, this is our first race weekend in high temperatures, and it's a struggle a little bit. Finally it all came together - after the first run in qualifying we weren't very happy with the car, made some changes, and I think we've learnt a lot about the car and how to run in these conditions, and when we've done a full season we'll feel completely up to speed."

DC: But unfortunately the season will be over and you won't be able to use it...

GW: "We'll have a new car; we're already starting to work on next season's car."

DC: I'll see if you toe the party line; what do you see as your expectations for the year?

GW: "Well certainly I want to be racing the top teams. It's a little difficult to know who they are at the moment; obviously Ferrari. I think it'll take a few races to settle in. I would have guessed the top teams were Ferrari, Renault, Williams, ourselves probably pushing ahead a little of McLaren. I didn't really expect Jaguar to be that strong, but I think an important thing to do in the first few races is to work out your strengths and weaknesses, and who your competitors are."

DC: David Richards said he wanted to be on the podium for a third of the races; is that realistic?

GW: "I think it's going to be tough to get on the podium that often, because there are probably ten cars at any given race that have got a reasonable chance of getting on the podium; maybe six at any given race and ten that can sometimes get there; and that's going to make it very tough, no doubt about it. If you're saying at Melbourne Ferrari was the strongest car, then there were five people trying to get into that third place, and not a big difference between them, so two Williamses and ourselves finished within twelve seconds of each other after 58 laps."

DC: It's tough because looking at winter testing you've made a quantifiable improvement, but everyone seems to have improved substantially this year.

GW: "They have done. I think certainly fourth is what we want to be aiming for, and we want to be close to the top three, and I think if you end up fifth in the Championship and one point behind fourth, which is one point behind third or something then it's a different flavour. We certainly don't want to be a distant fifth as we'd be disappointed with that, and we don't want to be a distant fourth either."

DC: I guess if the competition is close then a close fifth is almost across the line.

GW: "I think we can do better than that; certainly we're targeting better than that. And we have a few car developments coming at the next race, some aero developments coming up for Imola, another engine for Imola; so there's lots coming for this year."

Craig Pollock made three notable deals in his period at the top with BAR. First, and most controversially, he brought Jacques Villeneuve into the team. From a public relations point of view it was shrewd, although controversy rages to this day about the integrity of a team principal appointing a driver he personally manages. The second beneficial deal was to steer Honda's return to the sport in which they had so notably succeeded during the eighties and early nineties, although Pollock was unable to reap the rewards of this deal during his stewardship.

The third, and some might say most successful, deal was to appoint Geoff Willis as technical director at BAR shortly before his removal as team principal. Willis, a graduate of Cambridge University in mechanical engineering as well as a doctor of hydrodynamic engineering, has a good grounding in fluid dynamics from his time on the design team of the British America's Cup challenge from 1987 to 1990.

The third, and some might say most successful, deal was to appoint Geoff Willis as technical director at BAR shortly before his removal as team principal. Willis, a graduate of Cambridge University in mechanical engineering as well as a doctor of hydrodynamic engineering, has a good grounding in fluid dynamics from his time on the design team of the British America's Cup challenge from 1987 to 1990.

GW: "Not really, in the sense that I'm probably responsible for slightly over half of the budget; maybe more than that goes on the technical side. It was a matter of getting everything under control really, having a proper plan, having a proper measurement of your progress against the plan whether it is technical or budgetary. And just putting all this proper structures together is not rocket science, it's just doing it professionally, doing it properly."

GW: "Not really, in the sense that I'm probably responsible for slightly over half of the budget; maybe more than that goes on the technical side. It was a matter of getting everything under control really, having a proper plan, having a proper measurement of your progress against the plan whether it is technical or budgetary. And just putting all this proper structures together is not rocket science, it's just doing it professionally, doing it properly."

GW: "Well certainly Honda are very keen to get involved in the chassis side, not just the engine side, and they've got about thirty engineers in Japan and about twenty five engineers in BAR, and what we've done is sort of put them in the design groups at BAR. Most of them are all reasonably new to Formula One, but they're all automotive and analysis engineers, FE (Finite Element Analysis) engineers, aerodynamicists, so we're building up our strengths with quite a big extra percentage of engineers to help.

GW: "Well certainly Honda are very keen to get involved in the chassis side, not just the engine side, and they've got about thirty engineers in Japan and about twenty five engineers in BAR, and what we've done is sort of put them in the design groups at BAR. Most of them are all reasonably new to Formula One, but they're all automotive and analysis engineers, FE (Finite Element Analysis) engineers, aerodynamicists, so we're building up our strengths with quite a big extra percentage of engineers to help.

GW: "Well we have a hierarchy reporting to myself and the assistant technical director and the chief engineers, who are responsible for the technical leadership of their divisions or projects, project and planning and manufacturing, so that in mechanical and transmission, in electrical, in race engineering, in aerodynamics, in composites you've got these different groups. We have regular meetings at least once a week, sometimes twice a week between all the chief engineers, and we're the group that steers the car design and responds to problems and directions throughout the year.

GW: "Well we have a hierarchy reporting to myself and the assistant technical director and the chief engineers, who are responsible for the technical leadership of their divisions or projects, project and planning and manufacturing, so that in mechanical and transmission, in electrical, in race engineering, in aerodynamics, in composites you've got these different groups. We have regular meetings at least once a week, sometimes twice a week between all the chief engineers, and we're the group that steers the car design and responds to problems and directions throughout the year.

|

Contact the Author Contact the Editor |

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 10, Issue 13

Atlas F1 Exclusive

Interview with David Richards

Interview with Geoff Willis

Interview with Jenson Button

Interview with Takuma Sato

Articles

Every Other Sunday

The Paint Job: Part IV

Telling Teammates Apart

2004 Bahrain GP Preview

2004 Bahrain GP Preview

Bahrain GP Facts & Stats

Columns

The F1 Trivia Quiz

Bookworm Critique

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |