Atlas F1 Technical Writer

With half of the 2004 season completed and after two technically challenging Grands Prix in North America, Atlas F1's Craig Scarborough analyses the developments, surprises and disappointments delivered by the ten teams and the recent events and technical controversies

This is the time of year that the teams release their major updates to cure the issues picked in the first half of the season and not remedied by interim designs. It is the perfect stage to reflect on the cars and their design, as well as the critical issues raised in Canada and Indianapolis.

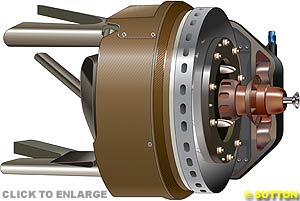

Brake Cooling at Montreal

Carbon discs were adopted in the eighties and have been standard equipment for decades, with greater stopping power over steel discs and the added benefit of light weight. This was offset by far greater heat rejection, causing problems with the parts surrounding the disc. While the problem of heat affecting parts around the disc were solved, there is still the problem of keeping the brakes themselves from overheating. This is the biggest problem with carbon brakes; overheating causes accelerated wear, eventually leading to thinned brake discs and subsequent failures. Checks are made during pitstops and via sensors in the brake callipers to ensure discs are not over worn.

Until 2000, brakes were cooled by a simple duct attached to the upright in a snorkel type layout. As a remedy to other aerodynamic problems (and not brake cooling), Ferrari adopted an all enclosing brake duct; this effectively made the duct into a chamber, sealing the entire upright assembly within the duct. The inside of the duct was fed cool air, making the bearings, sensors, brake callipers as well as the disc itself cooler. Contrary to popular belief these ducts do not hide a fan, which is surprisingly legal following a clarification from the FIA. Instead the duct is largely empty.

In Canada larger ducts are run to keep the brakes cooled for the frequent heavy stops from high speed. The ducts have to fit within the V of the suspension, and also within the dimensional regulations. These regulations were introduced to stop the disc type covers placed on the inside of the wheel rim to smooth the aerodynamic shape, and the rules specify the width and height the duct (described in the rules only as bodywork) must fit within. As with all bodywork rules, there are no tolerances and any infringement is disqualifiable, even if the team gained no advantage.

Toyota blamed manufacturing tolerances, that when added placed the duct just a couple of millimetres too far outside the wheel. Each of the teams had ducts effectively the same size as their legal versions, but the assembly placed the ducts inlet too far out into the airstream. This could have potentially placed the duct into an area where more air could be gathered, but bearing in mind the small amount of extra offset, this would not be a measurable gain. Instead, both teams lost their places and points for embarrassing mishaps that should never have happened.

Indianapolis Punctures

The Indy race was marred by several accidents, and in particular the major crash of Ralf Schumacher. While the first incident was a typical first corner crash between four cars, it led to carbon fibre debris littering the track and being picked up by following cars, which resulted in the two major tyre failures of Schumacher and Fernando Alonso.

Carbon fibre is by far the most abundant material on an F1 car, with only the engine, gearbox and wheels are made mainly from other materials. In the simplest terms, carbon fibre is cloth soaked in resin, much like fibreglass. However, the detail of the material makes the difference, creating the super stiff material adopted so widely around the cars.

The threads of the woven fabric can be brittle and their microscopic fibres can easily pierce softer materials. Many carbon fibre laminators have tiny black dots on their finger tips, a legacy of strands of carbon fibres being stuck into the skin while working with the material. When added to the stiff resin that moulds the cloth to its shape, the resulting effect creates a vicious serrated edge. As carbon fibre is stiff, it tends to shatter when presented with impacts outside of the designed load paths, hence in an F1 accident all the wings, bodywork and suspension shatter in millions of tiny sharp pieces.

When a hot, sticky and soft Formula One tyre meets these shards it will either cut the tyre immediately or, if the piece is smaller, will dig into the tyre until the tyre wears and is pushed through to cause a puncture. Formula One tyres are very heavily loaded, as the car is constantly cornering, accelerating or braking. The Indianapolis Motor Speedway sees a respite to this, with the long straight where the tyre is relatively stable, but as the cars brake for turn 1, the tyre once more becomes unstable and creates the conditions for the carbon to dig in and lead to a blow-out.

This was the case in Alonso's accident. Schumacher was unlucky, as the car was still building speed through Turn 13, loading the tyre as it both accelerates and corners. The tyre failed and put the car into a spin towards the lower apron before the car climbed the banking and hit the wall. Fortunately the car hit the wall backwards and at an angle, ricocheting the car up the track for quite some distance. The spin and the deflection off the wall reduced the possible load that Schumacher could have been subjected to.

These structures are small in comparison to the nose cone safety structures and have recently been required to pass a sideswipe test to ensure they do not fail in an angled impact, such as Schumacher's accident. As the car withstood the impact so well and the HANS device no doubt protected his neck from the whiplash, Ralf is a clear example that safety developments in F1 are making a difference.

Transatlantic tech

The recent pair of races in Canada and the United States both required cars with good straight-line and brake performance, with Indy demanding slightly more downforce to cope with the in-field section.

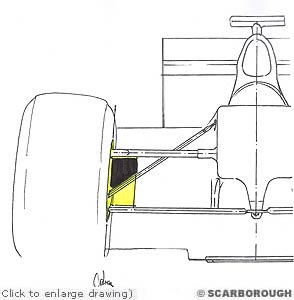

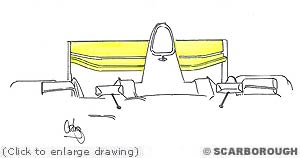

Drag is also created by other areas of bodywork, such as cooling outlets and brake ducts, hence the conflicting demands of brake cooling in Canada cost a few percent of overall aero efficiency. As has been explained many times in these technical reviews, another cause of drag is the vortex produced at the edges of the rear wing. The 3D curvature of most rear wings aims to reduce the downforce created at the endplate to lessen the vortex effect.

In creating their low drag wings for Canada, most teams opted for very curved wings with very shallow angles of attack, creating the greater proportion of downforce in the centre section. These wings were used by Renault, McLaren, Jordan and Toyota, with Williams also adopting a wing with a wide serrated gurney across the trailing edge to further reduce drag.

Front wings were reduced in chord and angle of attack, with Ferrari opting to run only two elements over their usual three element wing, allied to the Williams-esque endplates seen in Germany. Renault again ran a 2003 spec curved front wing.

Season to Date

Ferrari

Of all the teams on the grid, Ferrari were expected to see the biggest drop in competitiveness this year; the rise of Williams, the new McLaren and the young pretenders in Renault and BAR were all shod with Michelin tyres and expected to force Ferrari out of the points in many races.

Many believed that Ferrari had made a mistake with their evolution of the 2003 car in the F2004. But despite the media speculation, most had forgotten Ferrari had equalled BMW in the power race, and still had amongst the best chassis in 2003. Only the parc-ferme rule changes and Michelin tyres diverted the red steam roller last year.

After some less than inspiring test sessions over the winter, many felt their prophecy had come true. But it was at one of the last test sessions before Australia that Bridgestone merged the result of the construction development team with that of the compound team that the definitive 2004 tyre was produced; it was major step, and lead to Ferrari's early season dominance.

Only Renault's pace at Monaco saw Ferrari clearly beaten (before the tunnel incidents). Elsewhere BAR have been able to out-qualify the team and Renault beat them to the first turn, but none have retained a lead after the first stop - such is the F2004's race pace. The gains made by Shell's lightweight fuel allowing full tanks to be run with little impact on laptimes, and the originally tardy Ferrari manual launch control has improved to make it harder for the fast starting BAR and Renault teams to make a clear pass.

Williams

In terms of disappointment, Williams must be at the top of the list in 2004. After three consecutive years of progress resulting in many wins over the otherwise dominant Ferrari, the release of the FW25 was meant to be the final nail in Ferrari's coffin. A feature of the past few seasons has been Williams' impressive development of an initially poor car, so when the FW25 flew in testing from the outset, it seemed the flaws of previous seasons were overcome. Yet in the first half of the season the car has never seemed to have the promise to threaten Ferrari, or even keep ahead of BAR and Renault.

Finding where the car has gone wrong is not as simple as many suggest, with the radical design departure in the twin tusks and twin keels seen by many to be the main issue. More likely the problems lie in a multitude of areas: aero, chassis, tyres and engine.

Aerodynamically, the car seems conservative (ignoring the nose for moment). The rear end seems to be where the problems lie; the complex flip up arrangement and overly wide sidepods are at odds with the rest of the grid, and you will recall that last year the rear end came in for the most development. This is where the major Silverstone update will most likely be focused. The nose arrangement, while unorthodox, seems to offer advantages when the car is in yaw or roll, so it is not really a cause of problems.

However, there is a suggestion that the compromise in the nose is not its influence over the aero, but on the chassis. The weight required to make the nose and twin keels work, has raised the centre of gravity and taken away potential ballast, so as the Michelins require more and more weight on the front end, the nose has unknowingly compromised them. Add to this Williams' preference to run very light levels of downforce, which also doesn't suit Michelin's front tyre.

Just as Mercedes suffered and were slow to recover from the loss of beryllium as a material in the engine, BMW seems to have lost their way with the one engine per weekend rule. Ferrari and the Japanese suppliers have got over the hurdles, while BMW seem to have remained static and perhaps are no longer supplying the most powerful engine on the grid; they certainly don't by the race end, as BMW have only recently allowed full revs through the final lap in the races, to preserve reliability.

McLaren

After blitzing winter testing with the early released car, McLaren initially looked menacing, but later testing - after the release of the new Mercedes engine - soon revealed cracks in the package. After the failure of the MP4-18 to race due to chronic reliability problems, this was seen as a surprise. This year's MP4-19 takes a lot of its design from the 17D and the 18, while Adrian Newey still admits there are compromises in the car's layout with regard to fuel capacity and other design elements. While this seems absurd for a car so long in gestation, the strain on McLaren's resources to design and build so many chassis in the past three years has obviously taken its toll.

The problems with the MP4-19 lay in two areas. Pace is affected by aerodynamics - largely taken from the 18 and hastily revised with a new front wing, without being able to revise other fixed parts of the car, such as the nosecone, chassis, keels and sidepod fronts. McLaren still seem to suffer a lack of front end grip, and are not getting the Michelins working as well as possible.

Suspicions of where the mechanical failures occurred have pointed towards the major castings, originally made in the UK by a specialist and this year farmed out to a Mercedes foundry in Germany. The castings were substandard, leading to flexing crankcases and heads, ruining the internals as they spun in their offset bearings.

Another problem presented with the engine is the heat radiated with in the sidepods; McLaren have consistently run extra openings in the sidepods, with these initially being very temporary field based revisions and only recently being purpose made ducts. Lastly, the engine seems to struggle in retaining its pressurised pneumatic supply, often pit stops have been made to top up the nitrogen in the system only for it to fail soon after.

Pictures seen of the MP4-19B from recent testing have since provide a little more insight to the changes. As suspected, the radiators are indeed different to the 19. The usual McLaren upright coolers are now laid down, with the cooler split into two, to accommodate the shaped sidepods; the upper cooler is more upright while the narrower lower cooler is laid down more, but not in a V shape as with Renault or Sauber. As the upper cooler is much wider, it now passes under the main monocoque moulding, and a dedicated cooling outlet has been moulded into the chassis.

Cooling the inside of the sidepods still appears to be a problem area, as the sidepods were riddled with holes around the exhausts at the recent test in Jerez, Spain, suggesting McLaren aren't learning their lessons from the recent line of cars.

Renault

Early indications gave suspicions of a poor season for Renault, with an engine based on an old design, over the top sidepods that would never cool the engine, and the loss of their technical director. With these worries it's hard to gauge the true level of Renault's success this year; the chassis has again been praised for its composure and the engine in its debut year has proven to be on par with its power and reliability.

The team has not really competed at the very front until later races, and of course at the one-off Monaco race. It's true to say the engine doesn't have the power of the Ferrari, BMW or Honda, but it is closer to the output than the wide angle engine achieved in three years, and the engine makes up for its lack of outright power with much better fuel consumption, allowing the car to run lighter or longer, plus the engine is matched to launch control system that still beats all the other teams.

It is believed the launch control system (which is no longer an active system completely controlling the start and reacting to changes in wheel spin) uses three features; firstly the engine doesn't produce a lot of top end power but does so lower down the rev range, and this softer delivery allows the clutch to be fully released at lower revs and allows the tyres to grip and then accelerate.

Allowing this is a clutch release mechanism that detects the bite point accurately during practice starts around the warm-up lap and releases the clutch in a more controlled manner. This crucial control of the clutch is also improved, with the clutch paddles featuring a lock which sets the paddle to the biting point (again during the practice starts on the warm up lap), allowing only a secondary control to release the paddle to initiate the start.

Renault's handling has been well commented on for the past few seasons, and the inherent pace of the R24 chassis is not in dispute, but the team have taken some time to find a set up to exploit that grip. Before this the car was snappy and unforgiving, upsetting Trulli's more delicate driving style in particular. Their pace at Monaco was partly attributed to the flexible chassis coping much better with the undulations in the road surface. While this might not be true, Renault has returned to a brace over the engine to reinforce the chassis stiffness, a tactic employed in the design of the wide-angled engine installations.

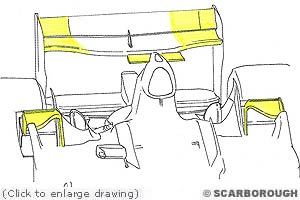

Aerodynamically the team have used the most bizarre solutions seen on the pitlane, with be-grilled sidepods, complex bargeboards and recently the two piece mid wing and shelf wing. Renault's ability to make complex shaped aero parts work is impressive, when most teams still use far more simple shapes that are easier to conceptualise, understand and design.

A return to the older R23 front wing was a feature at the Nurburgring, albeit with the current front wing endplates (FWEP); however the flat centre profile of the normal wing may not make the downforce required for the upcoming European circuits increasingly demanding maximum downforce.

BAR

Their pace in winter testing was not believed by many, who put the pace down to sponsor pleasing low fuel runs. But BAR's confident new car, with its all carbon gearbox and minimalist aerodynamic treatment, soon proved the testing times correct.

BAR were early adopters of extra wings and fences to improve rear end downforce, but surprisingly little other visible development has been evident, so the forthcoming upgrade for Silverstone should be interesting. One small unique touch are the brake ducts, which extend forwards and pick up clean air above the FWEP; these brakes, developed with Alcon, have proven effective. The cars basic weight is very low, allowing for plenty of ballast to be run; modifications to make it more secure were implemented after Takuma Sato's problem in Canada.

The car's use of its Michelins rates BAR amongst the top Michelin runners, and recent set up work with static camber and camber changes have brought some additional gains. Getting to know the French tyres has also driven aero development, with the initially simple FWEPs now featuring more shaping as the team understand how the tyre deforms during a lap.

Honda has produced an engine a major step ahead of its recent predecessors; although last year's Suzuka engine did hint at the power figures for this year, its development in size and reliability have also been impressive. However Sato's record of race finishes has been disappointing, with apparently major failures leading to plumes of oil and water trailing from the car.

Since the Honda in Jenson Button's car remains largely reliable, it has been a point of controversy as to why Sato is being affected so much. It can immediately be discounted that Sato is being handed inferior or indeed special engines, either on account of his B driver status or as Honda's preferred driver; their engines are identical, and are selected from the pool of units brought to each race.

The team have also looked at the driving styles and the driver's operation of the engine, which although controlled by a lot of electronics does still allow for variances in the aggressiveness of the throttle, and additionally the drivers use of kerbs sending shocks through the car and the drive-train to the engine. The team have also looked at the engines preparation when being installed and maintained in the car, but the true cause is still unknown.

I would point it towards Sato's style of using the engine in “unusual areas of operation”, as Geoff Willis tends to explain when something doesn't work or when something unforeseen affects it.

Sauber

There was an immediate controversy surrounding the car before it had even turned a wheel at its launch, when every commentator suggested the car was no more than a Ferrari replica. While the car does run a Ferrari 2004 engine and 2003 gearbox, the chassis and aerodynamics are Sauber's own, and the cars comparative pace to Ferrari on the same tyres suggests the commentators were wrong in their initial assumptions.

During the course of the season so far, the technical interchange between Ferrari and Sauber has been more apparent. Sauber have tested Bridgestone tyres, at Ferrari's request, at circuits Ferrari hadn't previously tested on, and Sauber driver Felipe Massa has tested for Ferrari. Some co-operation has also been evident with the sharing of the Sauber wind tunnel. While this may sound like unfair collusion, the joint tyre development program and wind tunnel work are more like commercial agreements and not linked to the sporting side of F1.

The C24's pace has seen Sauber racing at their true level in the midfield, never threatening the top teams but not drooping back to Minardi or Jordan either. The car is balanced and vice free, but is simply lacks the efficiency of the Ferrari, not having the downforce or mechanical grip to match. The chassis is weighty compared to most, with a modest amount of ballast added to the floor of the chassis, further emphasising the monocoque design was Saubers and not Ferraris. The move to a single keel over their trademark twin keel hasn't seen many ramifications, suggesting the potential gains of one solution over another are exaggerated.

Jaguar

After the promise shown last year, albeit largely in qualifying, Jaguar needed to show they could progress from their best season yet. When the car was launched the conservative design and immediate reliability problems with the new Cosworth engine sounded warning bells.

Pace wise the car has been around the same position as last year, showing better in qualifying in the hands of Mark Webber than in the race. Track time and race finishes all have been hindered by reliability, largely engine or hydraulic related. The car doesn't show as aggressive tyre wear as in 2003, but still fails to make the most of the Michelins over longer runs. Perhaps problems in the concept and layout of the car are hampering speed; the current Michelins need a lot of front end weight bias and careful control of camber, and Jaguar are notably running desperately placed ballast high up in the nose to push weight forwards at a cost to their centre of gravity.

This compromise could be down to two reasons; either insufficient space to add more ballast in the splitter or not having enough ballast to play with due to weightier components elsewhere on the car. I suspect the latter is the case. Jaguar also run the drooped front upper wishbones; as with the Williams this is a solution to meet the camber requirements laid out by Michelin at the end of last year, and neither team have found good front end grip. Development has been staid, with detail changes to the sidepod flip up treatments the main areas of visual development.

Toyota

Having made progress over their opening seasons Toyota had the benefit of their new windtunnel added to their experience over two seasons. The car's design was a conservative but progressive step for the team, but they seemed to have taken a step back in pace and returned to the rear of the midfield. Now on hand to sort the team into its expected position is Mike Gascoyne, with the hopeful “Mr Fixit” arriving at Toyota via Tyrrell, Jordan and Renault.

Changes are already afoot, with key staff assuming different responsibilities; first to change was the head of aerodynamics Rene Hilhorst, who remains with the team, but the head responsibility of the aero department now sits directly with Gascoyne. Gustav Brunner has been tasked with new car development, allowing him to put his conceptual skills to better use than running the whole chassis dept.

A major revamp of the car is due for Silverstone; while not badged a B spec it will be as fundamental as that. The chassis needed to lose weight to allow for more ballast to lower the centre of gravity; the shape will be similar, but the lay up of the carbon fibre will differ so new crash tests will be required. Aerodynamics are also on the task list and a new set up will appear for Germany; while this will be a major step no radical visual changes are expected.

From the new developments, the problems in the TF104 can be assumed; the cars lacks aerodynamic efficiency, meaning it cannot run a lot of downforce without a drag penalty. Equally the chassis will still not ride kerbs, although last year the handling imbalance created was aerodynamic and not mechanical. The engine seems to be overshadowed by the shortcomings of the chassis, although their pace at Indy suggests the car has power and reliability.

Jordan

Over the winter Jordan made a substantial change to the car by switching to a single keel, as well as adopting Cosworth's new CR6 (90 degree) engine, but otherwise the main design concepts from the 2003 car were incorporated into the EJ14. The resulting package seems only to have kept pace with the other teams and Jordan remains firmly stuck between the midfield and Minardi.

The car is struggling for aerodynamic efficiency, the comparative improvement in pace at the recent high speed races shows the car works well enough when downforce isn't required. The cars plight is best seen in qualifying, when the drivers can be seen with understeer trying to get the car into the corner and then oversteer as they try to power out of it. There has been little visible development to the car, with only tweaks to the winglets and a mid wing added for Monaco.

Minardi

It was disappointing to see Minardi launch a warmed over version of the PS02 when the Arrows A23 was tested as PS02B over the winter. None of the promising concepts of the Arrows car were adopted, although some of its data on carbon lay ups was apparently adopted invisibly within the weaves of the chassis. Additionally keeping with the CR3 Cosworth engine and the long established cast titanium gearbox have not seen the team progress.

The promise shown shortly after the Paul Stoddart's takeover has disappeared, and the team are no longer producing effective little cars on a budget. A rare early season aero update was put on the car featuring new sidepod fronts; the revisions were retained but appeared a hasty revision, rather than a considered re-design. Yet the car still suffers from both a lack of downforce and a lack of mechanical grip, which is evident from the stiff jumpy rides across the kerbs that lead to the qualifying problems for the drivers at Imola.

With the transatlantic race sequence completed, the season is at the halfway stage, and the teams are preparing themselves for the balance of the season, comprised of the classic European tracks followed by a string of flyaway races. The upcoming run of races includes both slow and fast tracks, as well as the testing curves of Spa and Suzuka.

Brake cooling has become an increasing concern for the teams. The FIA regulate the component sizes; brake discs are limited in diameter and thickness, while callipers are limited in the number of pistons and pads they can use. These restrictions place the brakes deep within a small diameter wheel, and the increased grip provided by the tyre war has brought brakes to the limit of development.

Brake cooling has become an increasing concern for the teams. The FIA regulate the component sizes; brake discs are limited in diameter and thickness, while callipers are limited in the number of pistons and pads they can use. These restrictions place the brakes deep within a small diameter wheel, and the increased grip provided by the tyre war has brought brakes to the limit of development.

In Canada, two teams had large brake ducts developed to the limits of the regulated dimensions, but had actually overstepped them. Williams blamed a duct shape that was developed but later discarded, yet somehow found itself installed on the race cars. This duct was no larger than usual but when matched to the wrong type of inner duct, the assembly stretched outside of the rules by quite some margin.

In Canada, two teams had large brake ducts developed to the limits of the regulated dimensions, but had actually overstepped them. Williams blamed a duct shape that was developed but later discarded, yet somehow found itself installed on the race cars. This duct was no larger than usual but when matched to the wrong type of inner duct, the assembly stretched outside of the rules by quite some margin.

Bearing the brunt of the load was the rear impact structure; this component is still relatively young in Formula One terms, having been part of the safety vanguard following Ayrton Senna's death in Imola ten years ago. It was aimed at reducing the violence of rear impact, whereas previously the stiff engine and gearbox unit would have transferred the load directly from the back of the chassis to the driver.

Bearing the brunt of the load was the rear impact structure; this component is still relatively young in Formula One terms, having been part of the safety vanguard following Ayrton Senna's death in Imola ten years ago. It was aimed at reducing the violence of rear impact, whereas previously the stiff engine and gearbox unit would have transferred the load directly from the back of the chassis to the driver.

As a result, most teams used their preceding tests at Paul Ricard or Monza to prepare their low downforce wing sets. These wings will be used again in Monza, the only other low downforce circuit left this year. To be clear, low downforce actually means low drag; if the cars could have downforce with no drag they'd take it, as it's the drag that slows them on the straight.

As a result, most teams used their preceding tests at Paul Ricard or Monza to prepare their low downforce wing sets. These wings will be used again in Monza, the only other low downforce circuit left this year. To be clear, low downforce actually means low drag; if the cars could have downforce with no drag they'd take it, as it's the drag that slows them on the straight.

Jordan raced a development set of winglets, featuring a curved leading edge to use the outer tip to direct airflow away from the rear wing. As these races were largely power circuits, many new specification engine were debuted.

Jordan raced a development set of winglets, featuring a curved leading edge to use the outer tip to direct airflow away from the rear wing. As these races were largely power circuits, many new specification engine were debuted.

Team by Team

Ferrari seemed to clear the barriers set by the one engine rule and rear wing restrictions without breaking stride, and their early adoption of mid wings to smooth the airflow to the rear wing were soon copied by others. Around the rest of the car the fastidious attention to detail continued, with the gearbox and rear suspension being compacted into a yet tighter package, with the sidepods and, in Germany, the new chimneys breaking with recent practice of running grills to vent the sidepods.

Ferrari seemed to clear the barriers set by the one engine rule and rear wing restrictions without breaking stride, and their early adoption of mid wings to smooth the airflow to the rear wing were soon copied by others. Around the rest of the car the fastidious attention to detail continued, with the gearbox and rear suspension being compacted into a yet tighter package, with the sidepods and, in Germany, the new chimneys breaking with recent practice of running grills to vent the sidepods.

The other problem area is the reliability of the Mercedes engine. It is not by chance that a major reshuffle of staff at Ilmor placed McLaren staff in key positions.

The other problem area is the reliability of the Mercedes engine. It is not by chance that a major reshuffle of staff at Ilmor placed McLaren staff in key positions.

|

Contact the Author Contact the Editor |

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 10, Issue 26

Atlas F1 Exclusive

Interview with Otmar Szafnauer

Bjorn Wirdheim: Going Places

Atlas F1 Special

2004 Half-Term Technical Report

2004 French GP Preview

2004 French GP Preview

French GP Facts & Stats

The F1 Trivia Quiz

Columns

Rear View Mirror

Bookworm Critique

Elsewhere in Racing

> Homepage |