Atlas F1 Technical Writer

Renault had a remarkable turnaround in fortunes in 2003, but do they have enough in every department to continue the upward momentum? Atlas F1's Craig Scarborough attended the team's 2004 launch at Palermo to assess their hopes for the the R24

Management

Mike Gascoyne's departure was long expected; the succession to his role was planned for some time (the role going to Bob Bell, who has been assisting Gascoyne in his role for years). Bell effectively is now running the co-ordination of chassis, aero and engine departs on a daily basis. Bell's role has not actually changed too much, which will be good for the short term stability of the team; whether he can be as influential and directional as Gascoyne will only be clear in the longer term.

Pre-dating Gascoyne's departure was Jean Jacques His' resignation; His has subsequently found a role in Ferrari road car division via the race engine workshop for a debrief. In the interim the new engine programme was project managed by Léon Taillieu and his team under Bernard Dudot's guidance. At the start of the year Rob White transferred from Cosworth to Renault as a replacement for His, but it was too late to influence the design of the R24 engine.

Philosophy

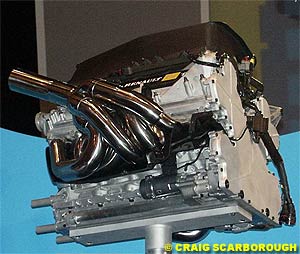

This shift in layout was as a result of the teams experience in narrower V10s, having never adopted the almost universal 90-degree format. As the team had to quickly develop a fully reliable 800km engine the learning curve for an all new 90-degree was too steep in the time available. However this does not imply that the engine bears any direct lineage to the 1990's units latterly badged as Supertecs; the unit is all new and brings experience from both the old 72-degree programmes and lessons from the 106-degree program. The result is a wholly new unit, Renault perhaps being the only team to adopt such a major shift for 2004.

While the resultant engine is taller and narrower than either a 90 or 106 degree unit, this has not been the driving force behind the super tight aerodynamic shape of the R24. Instead the aero philosophy was engine independent, progressing from the ideas behind Ferrari 2002-2003 cars. Creating as small a rear end as possible creates less drag from the rear wheels and better flow to the rear wing. Limiting this shape are five features; the side impact structures, radiators, cooling outlets, exhaust and gearbox. Renault has addressed each area, finding improvements in packaging in order to meet the requirements of the aerodynamic surfaces.

Aero

Starting this process off is a new front wing with a flatter, wider middle section to create a simple flow structure to pass within the turning vanes. Familiar endplates with a wavy foot plate has been seen on the Renault for two years. The bargeboards mimic Ferrari, with low forward extensions to more recognisable mid-placed bargeboards.

As described only innovative packaging has allowed the new sidepod shape. The side impact structures saw Bell give credit to a "great team" of designers at the factory in creating the slim floor section and rounded top edge while meeting the stricter crash tests. Radiators have commonly been angled and had curved side tanks fitted to fit within the sidepods shape; Renault have book-folded their otherwise normal radiator layout, splitting the coolers horizontally and pulling the split backwards to form a ">>" side profile.

To the rear the wing takes on the shape seen at Monaco in 2003, with the flap mounted remotely from the main plane on inward curving endplates. This design takes advantage of the longer rear endplate regulation not requiring the extra 10cm for the full height of the wing. The philosophy behind the complex mounting is that some of the high pressure above the main plane passes through and outside the curved endplate; this higher pressure meets the high pressure at the junction of the flap and endplate, reducing the strength of the vortex created as well as reducing drag in the process.

Mechanicals

Additionally, the attraction of begin able to make and quickly revise their own carbon case with in-house resources was offset by the extra workload placed on the carbon shop to produce the unit and equally the ease of "rapid prototyped" investment casting processes. The new Ti case is now cast in Europe rather than the American supplier (Cevolini CRP) in 2003. Atop the gearbox the spring damper layout of 2003 has been tidied, with vertical torsion bars operating three dampers.

Engine

No decision was made on the engine's V angle until the 2003 RS23 engine had run and the results of a series of reliability modifications from 2002 could be assessed. Although Renault considered the valve train modifications to counter the engines vibrations a success it was thought the 800km one engine rule would require yet more reliability, and the choice for a narrower angle was taken.

At the launch Renault were coy about showing the rear of the engine, as they were last year. Last year this was to hide the drive for one of the pairs of cams situated at the rear of the engine. This cam drive set up and the crankshaft counterbalances were to offset the vibration inherent in the unbalanced 106 degrees. It would be plausible to expect a similar set up on this year's engine, which is also an unbalanced layout. Adding fuel to this theory was lack of a straight answer from Rob White at the launch; instead he simply stated the engine had valves and cams driven by the crank. Other areas of the engine appear be conventional and aimed at getting the all new engine to 800kms without any loss in performance.

Renault hve been the team with the most respected chassis and electronics in Formula One, albeit one recognised as having a problematic engine. Moving into 2004 with its one engine per weekend rule and limited driver aids, Renault could be seen to be at a disadvantage. With the additional loss of their key technical directors on both the chassis and engine side things looked to be going awry for the Anglo-French concern. At their launch last week, Renault have come out fighting; headed by two new technical heads they have emerged as the sole team with a truly all new engine as well as adopting an extreme aerodynamic concept on the chassis side.

Having gone through a few years of similar aerodynamic and chassis concept mated to the wide angle V10 this year's car has adopted new philosophies; most significant is the dropping of the engine format for a narrow angle V10 from the unique 106-degree to an even less fashionable 72-degree. This change is a fundamental shift in engine policy, but originated in the engine department rather than the demands of chassis department.

Having gone through a few years of similar aerodynamic and chassis concept mated to the wide angle V10 this year's car has adopted new philosophies; most significant is the dropping of the engine format for a narrow angle V10 from the unique 106-degree to an even less fashionable 72-degree. This change is a fundamental shift in engine policy, but originated in the engine department rather than the demands of chassis department.

The net effect of the new sidepods adopts the popular approach of taking the flow early from the middle of the front wing, directing it inside small, low forward turning vanes and channelling it low around the sidepods, keeping it under the flip up to exit rearward away from the rear wing. Dirtier flow from the wings' downforce generating surfaces passes outside turning vanes and is kept clear of the clean flow. Lastly, flow passing above the front wing is left clear to pass over the tops of the sidepods and within flip ups by the rear wheels, giving a high quality flow to the rear wing.

The net effect of the new sidepods adopts the popular approach of taking the flow early from the middle of the front wing, directing it inside small, low forward turning vanes and channelling it low around the sidepods, keeping it under the flip up to exit rearward away from the rear wing. Dirtier flow from the wings' downforce generating surfaces passes outside turning vanes and is kept clear of the clean flow. Lastly, flow passing above the front wing is left clear to pass over the tops of the sidepods and within flip ups by the rear wheels, giving a high quality flow to the rear wing.

This radiator layout created problems for placing cooling outlets; with the lower radiator blowing its heat downwards necessitating outlets on the sidepods flank below the flip up. Above the split line there are numerous outlets, a large forward chimney, a grill and two as yet unused apertures for more grills. Technical boss Bob Bell explained that a map of outlet solutions has been created to match cooling outlet area against drag for oil and water cooling, to direct race engineers for the optimum solution. He also added that the "Swiss cheese-like" sidepods cover did create some interesting structural problems.

This radiator layout created problems for placing cooling outlets; with the lower radiator blowing its heat downwards necessitating outlets on the sidepods flank below the flip up. Above the split line there are numerous outlets, a large forward chimney, a grill and two as yet unused apertures for more grills. Technical boss Bob Bell explained that a map of outlet solutions has been created to match cooling outlet area against drag for oil and water cooling, to direct race engineers for the optimum solution. He also added that the "Swiss cheese-like" sidepods cover did create some interesting structural problems.

Mated to the new engine is an all new gearbox, which now uses a full cast titanium (Ti) casing. Last year Renault split the casing between a carbon upper and Titanium lower; a research program decided full Ti was the better direction to take for this year. Some of the issues with carbon cases were not resolved; the moulding being hard to predict weight wise until after production actually came out heavier.

Mated to the new engine is an all new gearbox, which now uses a full cast titanium (Ti) casing. Last year Renault split the casing between a carbon upper and Titanium lower; a research program decided full Ti was the better direction to take for this year. Some of the issues with carbon cases were not resolved; the moulding being hard to predict weight wise until after production actually came out heavier.

The choice of angle largely centred on the common 90 degree or the previously favoured 72-degree. While a 90-degree would be better balanced, Renault's lack of knowledge of how to make the configuration work counted against the format as time was limited. In the end the 72-degree engine came about as the synthesis of both the wide and narrow engine formats raced by Renault in F1.

The choice of angle largely centred on the common 90 degree or the previously favoured 72-degree. While a 90-degree would be better balanced, Renault's lack of knowledge of how to make the configuration work counted against the format as time was limited. In the end the 72-degree engine came about as the synthesis of both the wide and narrow engine formats raced by Renault in F1.

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 10, Issue 5

Articles

Stand and Deliver

Technical Analysis: BAR 006

Technical Analysis: Renault R24

2004 SuperStats: Winter Testing

2004 Countdown: Facts & Stats

Columns

The Fuel Stop

The F1 Trivia Quiz

On the Road

Elsewhere in Racing

> Homepage |