Williams-BMW's Technical Chiefs

Atlas F1 Technical Writer

Following a strong finish in 2003, the Williams-BMW team were seen as the favourites to stop Ferrari's dominance of the sport. Yet they had to wait until the season-ending Brazilian Grand Prix to clinch their first and only win of a disappointing campaign. Atlas F1's Craig Scarborough spoke to the team's technical director Sam Michael and BMW boss Mario Theissen about another frustrating Formula One season

Season Summary

Williams rolled out an all-new car at Valencia, Spain, in January 2004, boasting a radically different nose arrangement. Around the rest of the car the layout and design was consistent with several of the previous Williams machines. Early testing proved positive but as soon as the season was underway, it was clear the car lacked the same grip and handling as demonstrated by its rivals. As with the team in 2003, a substantial update package was engineered and introduced in several steps, and even as late as the last race of the year, Williams introduced major new parts. But most visibly was the loss of the twin tusk nose, and it now transpires its loss was as much down to its weight as to its aero performance.

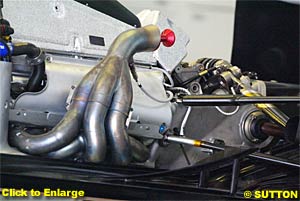

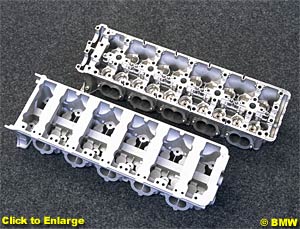

Meanwhile, the chassis deficiencies were masking the engine's performance. While BMW were still on the top rung of the performance ladder, the chassis no longer allowed it to shine. Almost unnoticed was the reliability of the unit, despite the longer mileage racked up from the new rules. As a partnership, the team also produced a new gearbox, fitting seven speeds in the space of last year's six speed unit. Using some BMW internals and a BMW casting, the unit let the team down at several races. This major cooperative project marked the start of BMW's greater involvement in the chassis side.

Sam Michael

CS: How is Gavin Fisher after his Bike crash?

CS: At the launch of the FW26, there was this huge amount of optimism and with the surprising design of the car at the front, but pretty soon we realised that the car wasn't on the pace. Was that because the car didn't meet the targets that you'd set, or that the target had moved?

Michael: "I think the main thing is we didn't have strong enough targets last year. There's always optimism at the start of a year, with a new car, because even if you're in trouble and haven't done enough work you still need to keep your head up and keep everyone motivated towards the same end goal, or else there's not much point being there. Basically, at the end of the first race you're always going to have one very happy team and a couple of reasonably happy team and the other seven disappointed. We were one of the disappointed teams. And because we took a couple of wrong directions on mechanical and aero, we spent the year fixing half of them, whereas the other half we can't really fix until next year."

CS: Did the car meet its design criteria on your targets?

Michael: "On some things it didn't, and on some things it did."

CS: I think everyone sort of points at the nose an awful lot and although I had a pretty good look at it, I looked at the rest of the car and it seems at first the rest of the car was quite conservative?

CS: Everyone became obsessed with it?

Michael: "Yes, that's right."

CS: It did seem to be tied to a specific shape of front wing, I noticed when you went to the new nose it was quite a substantially different wing you were hanging off that. Were they a function of each other?

Michael: "They were. We changed back to the other style of front wing main plane, because it worked better with a conventional nose if you like, that new wing worked also with the wide Mk1 nose."

CS: At the launch, you talked a lot about its yaw pitch and roll performance. Was that a short fall of it?

CS: The whole set-up along with the twin keels added a lot of weight, where perhaps you didn't want it

Michael: "If you do something like that, if you have a shorter nose like that, you have a shorter distance to absorb the load, and the only way you get around that is mass. It's quite a simple equation of length versus mass."

CS: Towards the end of the year, were you chasing where to put ballast around the car as a result of the changes?

Michael: "No, we had capacity on the car to store as much as what we needed. That wasn't a really big issue. During the year we did save quite a lot of mass up until the last race. That definitely helped the performance, and we also added quite a bit of downforce."

CS: The Michelin tyres didn't seem to provide the same level of performance as last year - almost in a reverse of character to Bridgestone's, where they seem to work well at the start of a stint and in shorter runs and then lose their durability

Michael: "It's always very difficult to separate out tyre from car. Obviously Ferrari produced a very good car this year, so it's pretty difficult to say everyone else's luck was because of the tyre. Then again, Bridgestone developed the wider front over the winter; they also made a couple of steps in casing and compound development. It's very difficult to quantify where the tyres are [in the performance equation]. All you know is that these are the tyres we've got, if they're helping us against Ferrari then that's great, if not then we have to do a bit more work ourselves."

CS: Did the car lack anything in getting the best from its Michelins?

CS: Media comment on how powerful the BMW engine was appeared to tail off this year, is there a feeling that they weren't the most powerful engine this year?

Michael: "It's very subjective to say that they're not, as a lot of it is based on speed trap data and things like that. It looks like the people who say 'we'll have 1000bhp next year' are not the fastest people in the speed traps and you'd think they would be. Because speed traps are a function of drag as well as horsepower, so it's very difficult to put them in any particular position."

CS: My perception is that BMW struggled more than most on the one engine rule; they seemed to restrict the revs during the early races...

Michael: "Who said that?"

CS: Mario Theissen himself! Was that because he was being more frank than other teams?

Michael: "We didn't struggle with engines at all with revs or power, that wasn't really a problem we had all year. It's a good engine and the use of its power during a race and the management of its revs has been good as well. I think, like other teams, we tend to use the engine when we can during the race. There are some stints in the race when you can turn the engine right up, then some stints when you are not under so much pressure and turn right down again. I don't think there's anything we do different to other teams on that front."

Michael: "I can't remember hydraulic problems in a race; we had gearbox failures in Spa, Bahrain and Monaco. Spa was the last one. We went too close to the limit on some things, which we have corrected that for next year's gearbox. But that was something we had to live with and made some corrections, as best we could. But without making a new gearbox we couldn't do everything."

CS: The pace of development for the team over the past two seasons has been immense. How does the team cope?

Michael: "Williams are set up to respond very well. We have a very good production facility and that's where we invested a lot of time and money - in production. That's what sort of helps you develop very quickly during the year. At the end of the day, that's something we're used to; it's part of F1."

CS: At every race, since you introduced the sidepods package at the French GP, there was a new part, all the way up to the new floor at Shanghai...

Michael: "Yes, and a new front wing for Suzuka."

CS: Is that a Negative thing, almost chasing your tail?

CS: TV footage shows the front wing flap somewhat deflecting under load, so to speak. Is that something designed in? How does it come within the FIA rules?

Michael: "I don't know how much of that comes from the camera moving - there are shots where stuff like that moves. I think our front wing is within the rules; it passed all the deflection tests from the FIA. They have a set amount of test they do. The FIA can do deflection tests on the whole car, they can test it on anything, and they do indeed do so."

Mario Theissen

CS: With this year's one engine per weekend rule, can you explain the impact it had on engine development and how you worked around it?

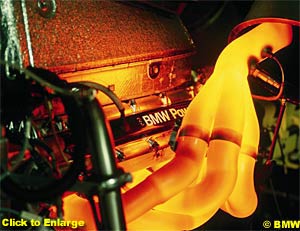

"Looking back the P84 was, in my view, certainly the benchmark in terms of power in race trim. In terms of reliability, we had one engine failure in the race in Malaysia and we had to change an engine on Friday in Monaco. If you combine power output and reliability I think the P84 was the benchmark again."

CS: On outright power or drivability...?

Theissen: "Outright power, primarily."

CS: How much were the revs restricted from lasts year's 19,000 rpm?

Theissen: "It wasn't much of a difference; we ran 19,000 rpm all the year through in qualifying and by a certain time of the year in the race. We were a bit more on the safe side early on in the season. We didn't start with 19,000 rpm, we went up to basically what we had last year."

CS: With revs limited slightly, was the engine tuned for drivability?

CS: Did the engine weight or dimensions change from last year?

Theissen: "It was heavier but same size and not much [heavier]. The weight increase was certainly below 5% (about 4-5Kg)."

CS: No significant development steps were announced during the season. Was it a case of race-by-race development?

Theissen: "I wouldn't say it was new steps in terms of power at every race, it was like a slow continuous improvement. A power step may be every third or forth race. Certainly every race the engine was different in some respect. We were developing the engine throughout the year for power increase or reliability improvements, so basically there was not at any race the same spec as from the race before."

CS: What kind of steps in output were made during the year?

CS: Surface treatments have helped achieve the mileage?

Theissen: "I cant really speak about what we do, it's the mechanically highly stressed parts of the engine, crank train and valve train and we try to limit wear by surface treatments and that's why it basically became more important with double engine life."

CS: Did you run oil development to assist with reliability over 800km ?

Theissen: "We worked with our lubricants partner Castrol throughout the year in developing the oil, shaping it to the needs of the new engine. But there hasn't been a basic difference in formulation."

CS: Williams BMW appear to use a much larger airbox, is that correct?

Theissen: "It's part of the design process of the car - you have conflicting targets, the engine builder was like a huge and massive airbox in order to catch as much air as possible and to create some dynamic pressure. On the other hand is the aerodynamic efficiency. You always have to do the trade off. We have brought 3D flow simulation to a very high level and we are able to predict the behaviour of the airbox to optimise the shape through simulation, rather than on experimental basis."

Theissen: "Power improvement had priority over fuel efficiency."

CS: Will BMW look to expand its involvement into chassis side?

Theissen: "We have got together on electronics and we are giving some input on the aero side, especially in simulations. We are working with Williams on a lot of experimental work."

CS: Where was BMW involved this year?

Theissen: "Primarily the power train; the drive train, the gearbox. We are involved with the design and development as well as the manufacturing. For example, this year the gear case was cast at BMW and some gears were manufactured by BMW."

CS: So were they BMW gear problems in some of the races this year?

Theissen: "The gearbox is joined area of development!"

CS: Were the problems mechanical or control related?

Theissen: "It was mechanical problems."

CS: How did the manual launch control develop?

CS: Were there problems with manual launch control, like the clutch problems?

Theissen: "It was basically the drivers who had to learn how to start, and it is quite tricky with a peaky engine. To do that, they had to find out what slip ratio would accelerate the car best. It's not just the characteristic of the power, but also how the clutch comes in. To exactly the right engine speed, the right engine load and the right way to drop the clutch to make the car leave the start. With many cars - not just ours - we saw some problems. It's only what we saw three years ago when launch control was allowed, it only takes a few months to get experience with it. That's what we saw this year, again in the second half of the year we got much better."

CS: Once the driver releases the clutch, it's a point of no return, the driver hasn't time to intervene, the electronics cannot intervene. If he gets it wrong, it's too late?

Theissen: "The behaviour of the clutch is not linear with time, so if you arrive at a certain point, at the bite point, the characteristic of the clutch changes because of the heat induced. So that makes it especially difficult. It's not that you rely on a certain point, which is stable through the start procedure; it changes all the time and so you quite easily over-rev or kill the engine."

After a great season in 2003, where Williams-BMW were challenging for race wins, pole positions and the World Championships on a regular basis, there was great expectation, going into 2004, that the Grove-based team would be the superior constructor. At the launch of the FW26, the twin tusk nose split opinions on whether these expectations would be met or not. Equally, with BMW topping the power and RPM league in 2003, most felt they had enough advantage over their rivals to stay ahead of the pack.

But, Williams had another poor year, where their car wasn't up to speed until a massive effort hauled them up to their competitors' level at mid season. Many cynics felt vindicated that the twin tusk nose and complicated twin keel chassis were to blame. In the final analysis, Williams Technical Director Sam Michael explains to Atlas F1 how the team developed in 2004, and BMW's Head of Motorsport Mario Theissen tells Atlas F1 about the one-engine-per-weekend rules and the expansion of BMWs technical interests beyond the engine.

But, Williams had another poor year, where their car wasn't up to speed until a massive effort hauled them up to their competitors' level at mid season. Many cynics felt vindicated that the twin tusk nose and complicated twin keel chassis were to blame. In the final analysis, Williams Technical Director Sam Michael explains to Atlas F1 how the team developed in 2004, and BMW's Head of Motorsport Mario Theissen tells Atlas F1 about the one-engine-per-weekend rules and the expansion of BMWs technical interests beyond the engine.

Sam Michael: "He's fine now and he's on crutches and in a wheel chair sometimes, but he's here working every day and here full time."

Sam Michael: "He's fine now and he's on crutches and in a wheel chair sometimes, but he's here working every day and here full time."

Michael: "Yes, there was probably some area that we tried to correct during the year, to make sure we pushed the boundaries further, but there is only so much you can do in a year. But on the nose, from our position it produced more downforce and potentially open up a different area for development on the FW26 which why we went for it, but ultimately it didn't prove the way to go. As far as we're concerned it's just an aerodynamic part that you have on the car, it's no different to us changing a flip up or a winglet - which we did six or seven times in the year, but because [the nose is] so visual at the front of the car, it means people think it's a lot bigger than what it is."

Michael: "Yes, there was probably some area that we tried to correct during the year, to make sure we pushed the boundaries further, but there is only so much you can do in a year. But on the nose, from our position it produced more downforce and potentially open up a different area for development on the FW26 which why we went for it, but ultimately it didn't prove the way to go. As far as we're concerned it's just an aerodynamic part that you have on the car, it's no different to us changing a flip up or a winglet - which we did six or seven times in the year, but because [the nose is] so visual at the front of the car, it means people think it's a lot bigger than what it is."

Michael: "Ultimately, it came down to the mechanical loss as well as aero losses, that's why we looked at something different during the season."

Michael: "Ultimately, it came down to the mechanical loss as well as aero losses, that's why we looked at something different during the season."

Michael: "The car has an ability to generate a lap time based on how it uses its tyres, which comes from weight and aero, and when you get to the track then you work on the set up to make sure the car's balanced. But there was nothing lacking on the car in terms of specifics, it was everything. We just needed to improve everything on the car."

Michael: "The car has an ability to generate a lap time based on how it uses its tyres, which comes from weight and aero, and when you get to the track then you work on the set up to make sure the car's balanced. But there was nothing lacking on the car in terms of specifics, it was everything. We just needed to improve everything on the car."

CS: One area, as with most teams, is problems with hydraulics and gearboxes causing troubles in practice and races. Is that something the team overcame since Antonio Pizzonia's retirement in Spa?

CS: One area, as with most teams, is problems with hydraulics and gearboxes causing troubles in practice and races. Is that something the team overcame since Antonio Pizzonia's retirement in Spa?

Michael: "Not really. Whenever you are behind, you need... It's not chasing your tail, it's chasing the others. It's a matter of developing your car as fast as you can to try to get as close to the other teams. Normally, in most years, it's beneficial to develop up to the last race as all that development normally goes into next year's car. It's a little bit different this year, as the cars are so different for 2005, so it's more expensive as you can't carry over all the parts, so it's more tempting to give up on this year's car. But you can't, really."

Michael: "Not really. Whenever you are behind, you need... It's not chasing your tail, it's chasing the others. It's a matter of developing your car as fast as you can to try to get as close to the other teams. Normally, in most years, it's beneficial to develop up to the last race as all that development normally goes into next year's car. It's a little bit different this year, as the cars are so different for 2005, so it's more expensive as you can't carry over all the parts, so it's more tempting to give up on this year's car. But you can't, really."

Mario Theissen: "Obviously it was quite a challenge for the engineers to double the lifetime of the engine on mileage. We took up the task in three steps: first step was to get to a reliable 800km engine for the first race, which we managed to do. The second step was to make the maximum power and engine speed available not just for one qualifying lap, but also during the race, which was achieved by the Spanish Grand Prix. So since Barcelona we were able to run at almost 19,000 rpm in the race, even in top gear - which is unusual in F1 to go up in top gear, up to the same engine speed. The third step was obviously power improvements throughout the season.

Mario Theissen: "Obviously it was quite a challenge for the engineers to double the lifetime of the engine on mileage. We took up the task in three steps: first step was to get to a reliable 800km engine for the first race, which we managed to do. The second step was to make the maximum power and engine speed available not just for one qualifying lap, but also during the race, which was achieved by the Spanish Grand Prix. So since Barcelona we were able to run at almost 19,000 rpm in the race, even in top gear - which is unusual in F1 to go up in top gear, up to the same engine speed. The third step was obviously power improvements throughout the season.

Theissen: "No there was not a big difference - in fact we went for the same power curve as last year; peak power was achieved at the same engine speed as last year."

Theissen: "No there was not a big difference - in fact we went for the same power curve as last year; peak power was achieved at the same engine speed as last year."

Theissen: "Well, we finished last year (2003) with above 900bhp, we started below 900bhp this year and we ended up about in the same region as the end of last year. We recovered from the power loss that resulted from the doubling of the engine mileage through the season and finished again above 900bhp."

Theissen: "Well, we finished last year (2003) with above 900bhp, we started below 900bhp this year and we ended up about in the same region as the end of last year. We recovered from the power loss that resulted from the doubling of the engine mileage through the season and finished again above 900bhp."

CS: Did you work specifically on fuel efficiency, to decrease in race laptimes by running less weight in fuel?

CS: Did you work specifically on fuel efficiency, to decrease in race laptimes by running less weight in fuel?

Theissen: "You need all the people, all the engineers together. So it's the people who deal with the gearbox, engine, clutch and obviously chassis people. It's about mechanical traction of the car, and also the reliability of the engine."

Theissen: "You need all the people, all the engineers together. So it's the people who deal with the gearbox, engine, clutch and obviously chassis people. It's about mechanical traction of the car, and also the reliability of the engine."

|

Contact the Author Contact the Editor |

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 10, Issue 49

Interview with Nick Heidfeld

Interview with Williams Technical Chiefs

Bookworm Critique

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |