Formula One's Engine Specifications?

Contributing Writer

Current Formula One engines are based on complex technology that is more than a century old, but the manufacturers have had no reason to consider their options due to lack of competition. Engineer Leonel Corona puts the case forward for the Wankel rotary engine, and explains why Minardi and Jordan would be well served to push for its introduction in the sport

These specifications rule out any other type of engine, for example, the oscillating or the Wankel rotary type. And this is a shame, because it curtails the development of different technologies that could be applied to racing competition and that could also benefit normal street cars.

This was an event that could have changed the face of competition and technology in the years to come, but as always, big car-makers' interests came out on top. How could a company such as Mazda, with a little engine that had but a few moving parts, put the giants to shame? It was sheer madness. And they, the giants, put an end to it.

The same is happening in Formula One. Next year, engines are required to last an entire race weekend, in an attempt to 'save money' for the engine makers and the teams. In my opinion, this new rule will not only be more expensive, but it will also put the team and the drivers in a more precarious position, since they will be penalized for engine failures. Why penalize the drivers? Obviously they are innocent if the engine manufacturers supply grenades instead of engines. Why penalize the teams? Why not just restrict the number of engines that a team - or a car, for that matter - can have for an entire weekend? And lastly: why restrict engines to an extremely complex technology that is a century old, and becoming obsolete?

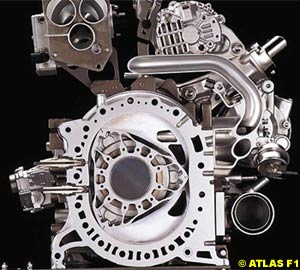

Clearly, the Wankel engine has far more benefits than the typical reciprocating type. For one, it has fewer moving parts. In the Mazda 4-rotor Wankel engine used at Le Mans there were only 5 basic internal moving parts! These were the four rotors and the drive shaft. Compare this to a 10-cylinder F1 reciprocating engine that has about 1000 internal moving parts.

Reciprocating motion is the Achille's heel of the piston engine. Things stop and start again in the opposite direction twice for every revolution. These start-stop cycles exert tremendous loads on the internal components such as pistons, connecting rods, connecting pins, valves, valve springs (replaced by pneumatic return in current F1 engines), valve trains, camshafts, lifters, pushrods and crankshafts. Any of these components can fail, causing the retirement of the race car from competition.

Consider Jordan's plight: it is bound by contract to receive year-old Ford engines, which in fact, in 2004 will be the engines used by Jaguar this past 2003 season! And, of course, these engines were not designed to last an entire weekend. What will Ford provide to Jordan? It is difficult to believe that Jordan will receive the same engine specification that Jaguar will get for this coming racing season. The most likely assumption is that these 2003 engines will have to be restricted to a lower RPM and horsepower rating to abide by next year's ruling, putting Jordan in a more precarious situation and making it still less competitive than it was this past 2003 season!

It is obvious that the big car manufacturers are behind the reciprocating engine ruling. They have too many interests to lose if a new technology emerges which is better than theirs, and they must know that Wankel engines are by far much better engines. Think of the investments they now have in tooling, parts, manufacturing plants and equipment. These could hardly be replaced without great economic losses.

If the FIA were to modify today the engine specification rule in all categories and allow the use of equivalent displacement non-reciprocating engines, the big manufacturers of reciprocating engines would have a few years of uncontested supremacy, until an adventurous firm, such as Mazda, could compete on an equal level introducing Wankel rotaries. Notice that the key words are 'equivalent displacement', a concept which was the primary argument that finally banned Wankel engines from Le Mans. The problem here is the interpretation of the factors that define displacement.

Displacement, for any engine, can be defined as the sum total of positive combustion chamber volume increases for one complete revolution of the main shaft (crank or eccentric, in the case of the rotary). In a reciprocating engine with pistons and cylinders, the displacement is the volume of the cylinder when the piston is at the lowest point of its travel, multiplied by the number of cylinders. Very simple, indeed. But in a rotary Wankel engine, this method of calculating the displacement is impossible, for there are no cylinders involved.

The rotary piston, or the rotor, is shaped like an equilateral triangle with curved sides and moves within a stator, or trochoid, in a motion known as epitrochoid, which allows for volume changes within the 'combustion chamber'. There are always three concurrent Otto cycles taking place during one complete rotor cycle, each corresponding to one of the sides of the rotor: intake, compression, combustion and exhaust. The fuel-air intake ports and the exhaust ports are opened and closed (exposed would be a better word) as the rotor travels inside the stator, rendering traditional valves useless.

Since each side of the rotor goes through the complete Otto cycle per revolution, the swept volume as it revolves about the stator is taken as its true volume, which multiplied by the number of rotors, gives us the total displacement. But since the rotor has three sides, it can be argued that in fact it has the equivalence of three pistons, and that the total volume is the swept volume of each side multiplied by three, and then multiplied by the number of rotors, which is absolutely wrong.

The rotor actually revolves at one third the speed of the eccentric shaft, which is the reason only one chamber's displacement is used in the calculation. This may seem hardly fair, if compared against a normal reciprocating engine, but this is precisely the advantage of having a rotary engine. For each rotor revolution, there are three revolutions of the drive shaft, whereas in a reciprocating engine, the crankshaft must rotate twice for a complete cycle to take place. This is the reason why so much power can be obtained from such small engines.

By the facts mentioned above, it can be seen that on a rotary, each rotor fires once per eccentric shaft revolution. In a piston engine, only half of the combustion chambers fire for a given revolution. This means that a two-rotor engine fires as often as a four-cylinder engine. However, the power stroke duration in a rotary is 50% longer, it being 3/4 of a main shaft revolution to the piston engine's 1/2. This makes a two-rotor engine similar to a six-cylinder reciprocating engine! The Mazda 787B prototype that won Le Mans in 1991 had four rotors, which means that it had, in equivalence (in power output, not in displacement), a twelve-cylinder reciprocating engine. This little engine ran for 24 straight hours in racing conditions, more than 8 times what today's F1 engines do in a normal race. When it was stripped after the race, no wear could be observed, as in fact it looked like new.

The fact is that Mazda has completely revised its rotary since then, and has made it even better. It is more fuel-efficient, which was a major concern back then, and it also runs with lower emissions, obtaining more power at the same time. The new RENESIS powerplant for the all-new Mazda RX-8 is a two-rotor, normally-aspirated rotary that delivers up to 228bhp for a six-port version, and 197bhp for a four-port type, from a displacement of 1.3 litres! All this in a production powerplant, designed to meet the world's most stringent emission standards, weighing 200 pounds, twelve inches wide, fourteen inches high, and seventeen inches long! Think of what it could do in a three- or four-rotor version, specially prepared for racing.

All other things being equal, like intake breathing, the horsepower of an internal combustion engine is directly proportional to its RPM's. The Wankel engine breaths extremely well at high RPM's due to the absence of valves getting in the way of the intake and exhaust ports. And, unlike all piston engines, the Wankel rotary is in complete and precise balance, just like a turbine or electric motor. Despite common beliefs, it is impossible to precisely balance any piston engine, as there are always reciprocating parts that oscillate back and forth.

It might be surmised from this that the Wankel engine is able to run at unlimited RPM's because there are no reciprocating parts. This is wrong. The Wankel rotary also has its RPM limits, mainly in the form of centrifugal force. The weight of the rotor spinning around the center of the eccentric shaft creates a tremendous centrifugal force on the rotor bearing at speeds of 10,000 RPM or more. Turbine engines are also subject to the same centrifugal force limits on its compressor and turbine blades.

Despite RPM restrictions, the Wankel can rotate much faster than an equivalent HP piston engine, adding to its already huge intrinsic power-to-weight ratio advantage. Additionally, this centrifugal load due to the weight of the rotor never changes direction on the eccentric shaft at high speeds, so a cracked or broken shaft on a Wankel rotary is unheard of. This is why the Wankel rotary engine designer can afford to make the rotor out of low cost and extremely durable but heavy cast iron, among other things.

Beside the power advantage, the rotary engine has other advantages that make it extremely attractive to Formula One constructors, or for any other type of racing cars, for that matter. First and foremost, it is extremely simple and has but a few moving internal parts. As mentioned before, the only moving internal parts are the rotors and the eccentric shaft. There are no pistons, connecting rods, connecting pins, valves, valve trains, timing chains or gears, or camshafts. It is also very small and light considering the power obtained. Its center of gravity is very low, making it similar to the Renault RS23 wide V-angle in that respect, and which gave the French team marked advantages in chassis handling and behaviour over its competitors.

The torque curve is incredibly flat, since power is applied to the shaft in every revolution, not once every two revolutions as is the case in reciprocating engines, resulting in a smoother and more constant acceleration. There is no need for the use of exotic alloys, as in reciprocating engines, to help reduce weight in order to alleviate the acceleration factor of pistons, or to reduce the stresses of connecting rods, connecting pins, and the crankshaft, to name a few. And think about this: the rotary engine itself is modular, having independent rotor housings that can be 'sandwiched' together to form a two-, or three-, or four-, or whatever-number-of-rotors assembly. Need to change a defective rotor? Unbolt the entire assembly, remove the faulty rotor housing, and replace it with a new one! And to top it all off, there's another factor that makes the Wankel so interesting: its durability. It could theoretically withstand not one, but almost half of Formula One's weekends, with practically no maintenance.

Le Mans 1991 proved what the Wankel rotary is capable of achieving, and the hindsight of twelve years should render better, more efficient, and more powerful and reliable rotary engines.

Sounds interesting? It should. You might accuse me of being naive, or perhaps of being a dreamer, but the evidence is there for all to see. Perhaps Eddie Jordan and Paul Stoddart should start lobbying to allow Mazda to enter the F1 fray. With their Wankel rotaries, of course. The only thing I would regret would be the passing of the symphony created by the roar of twenty V10 engines going full blast. With rotaries, it would probably sound more like a chamber orchestra. But it's a fair price to pay, is it not?

The FIA's Formula One Technical Specifications, in Article 5 concerning engines, state:

5.1 Engine specification:

5.1.1 Only 4-stroke engines with reciprocating pistons are permitted.

5.2 Other means of propulsion:

5.1.2 Engine capacity must not exceed 3000 cc.

5.1.3 Supercharging is forbidden.

5.1.4 All engines must have 10 cylinders and the normal section of each cylinder must be circular [sic].

5.1.5 Engines may have no more than 5 valves per cylinder.

5.2.1 The use of any device, other than the 3 litre, four-stroke engine described in 5.1 above, to power the car, is not permitted.

In 1991, Mazda competed against the world's automotive giants at Le Mans with its 787B prototype car. It made history by winning the race with a four-rotor, normally-aspirated peripheral-port Wankel engine that developed over 700 BHP and displaced approximately 2.8 litres. This is far less than the maximum displacement allowed. What did the organizers do? They banned the use of such engines the following year.

In 1991, Mazda competed against the world's automotive giants at Le Mans with its 787B prototype car. It made history by winning the race with a four-rotor, normally-aspirated peripheral-port Wankel engine that developed over 700 BHP and displaced approximately 2.8 litres. This is far less than the maximum displacement allowed. What did the organizers do? They banned the use of such engines the following year.

It is a tribute to manufacturers such as Ferrari, BMW, Toyota, and Mercedes that engine failure was almost nil this past season. It says a lot about the perfection these manufacturers have achieved in these complex engines. But this has cost the engine manufacturers involved in F1 great amounts of money and effort. This is why F1 engines are so expensive. This is the reason why privateers such as Jordan, Minardi and Sauber are always on the brink of bankruptcy. And instead of spending their money on the development of the chassis and other technologies to make their cars more competitive, they squander it on unreliable engines that, to top it off, will only bring them penalties this coming 2004 season.

It is a tribute to manufacturers such as Ferrari, BMW, Toyota, and Mercedes that engine failure was almost nil this past season. It says a lot about the perfection these manufacturers have achieved in these complex engines. But this has cost the engine manufacturers involved in F1 great amounts of money and effort. This is why F1 engines are so expensive. This is the reason why privateers such as Jordan, Minardi and Sauber are always on the brink of bankruptcy. And instead of spending their money on the development of the chassis and other technologies to make their cars more competitive, they squander it on unreliable engines that, to top it off, will only bring them penalties this coming 2004 season.

About the author:

Leonel Corona has been a Formula One fan since the early 1960s. Although himself an electrical engineer, he's been in love with machinery since an early age, and have had a love affair with cars since then. Having attended several sportscar events in Mexico and seen the Wankel engine perform to superiority, he developed a deeper interest in these "little beasts" as he calls them.

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 9, Issue 48

Articles

F1 at a Crossroad

Should Engine Specs be Changed?

Sixteen Sundays, Part II

2004 Countdown Facts & Stats

Columns

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |