Renault Innovations in Formula One

Atlas F1 Technical Writer

Since making their debut in the 1977 season, the Renault Formula One team have always been breaking new ground in terms of technology, ignoring the established routes and opting for innovative approaches. Atlas F1's Craig Scarborough reviews Renault's history of technological breakthroughs, from the first turbo engine to the innovative OPT system

The eighties dawned and Renault were winning races and supplying engines to other teams. A change of heart lead the team to leave Formula One briefly, returning with a new breed of engine, the V10, at the end of that decade. Such was Renault's dominance in the nineties they left F1 once more, only to return in the new millenium with another ground breaking engine, the wide angle V10. But this time as a full manufacturer, allowing Renault to demonstrate their undersung chassis technology as well as their engines.

For nearly 30 years, Renault has used F1 as a platform to learn technology and show the world how it applies that technology.

Before F1

Pre dating their involvement with Formula One, Renault had a motorsport history throughout the first half of the century dating right back to the Renault brothers original business in 1899. Post-war the business expanded and with the bought-in know-how from the specialist Gordini and Alpine factories, Renault's motorsport involvement largely revolved around national production based series, with most successes coming in rallying and saloon car racing. At the start of the seventies Renault expanded its motorsport program with a single seater series named 'Formula Renault'.

By the mid seventies Renault had derivatives of its Gordini V6 engine running in Formula Three cars, winning two successive European championships. As part of the Alpine rally programme a young French Engineer named Bernard Dudot had been experimenting with turbo-charging a Gordini V6 engine for use in the Alpine coupe. This effort did not go unnoticed and was to form the backbone of Renault's future technical direction. Dudot was dispatched to America where Garrett, the turbocharger manufacturers were based and where Indy cars used simple turbocharged engines. This exposure was key to Dudot's subsequent designs.

Turbo charging was not new but underdeveloped and rarely applied to motorsport. Many of the world class series such as endurance racing and Formula One still had equivalency equations in the engine rules dating from the use of supercharging in the thirties and forties.

In 1975 Gordini were commissioned to design a small capacity unit for turbo charging. This initially found a home in the Alpine prototype chassis for 'Le Mans' and an outright success was won at the 24 hour race in 1978. While Renault had taken on the world at largely French or European-based championships, it was Formula One that the constructor had targeted for their true international debut. At the time, Formula One ran three litre engines, with most of the teams buying the Ford Cosworth DFV (V8) engine, with Ferrari running 12 cylinder units. Following the rule books 2:1 equivalence formula, Renault worked out they could downsize their V6 engine to 1.5 litres to compete with the three litre normally aspirated engines.

Principles of Turbo Charging

The first fan is driven by the primary exhaust pipes coming out of the engine, the pressure of the gas spins the fan and the gasses flow towards the middle of the fan and out through the centre into a secondary exhaust pipe and in the atmosphere. This part of the turbocharger is known as the turbine.

The second fan is now driven by the motion of the turbine via the shaft and pulls air in from the centre of the fan accelerating it and passing it through an outlet on the outer face of the casing, this part is known as the compressor. The high pressure air from the compressor can now be fed back into the engine via a sealed duct known as plenum chamber.

The problems associated with turbocharging are many fold. The action of pressurising the air in the compressor makes the temperature of the compressed air very high. This creates problems with combustion and hence limits power, the air (known as the charge) needs to be cooled. Secondly the turbine needs exhaust pressure to spin the compressor, at low revs the exhaust pressure drops and the fans slow down, and less power is produced while the turbine regains the lost speed. This is known as turbo lag.

The opposite of this problem is over boost, where if the turbo where allowed to spin up too fast too much pressure (or boost) would be created requiring a valve in the system to release the excess pressure. Allied to these problems is the huge amount of heat created in the turbo charger itself and in the engine, now creating over twice the power it would otherwise, so water and oil cooling is critical.

The First Renault F1 Turbo

The small car had innumerable teething problems from chassis and in particular engine. The effect of turbo charging places great thermal demands on the engine and oil system, the background knowledge of turbos in European sport did not exist. The small car liveried in Renault colours was tagged with the name "The yellow teapot" such were its cooling problems.

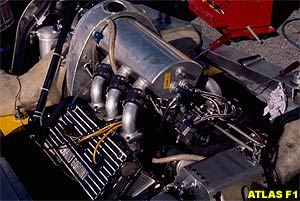

The engine adopted a single turbo layout, a format still used now in Indy car engines. A single turbo fed by the primary exhausts was mounted behind the engine, while the outlet from the compressor routes directly and un-cooled into the plenum chamber. This layout demonstrated that if the power could be produced reliably, the smaller overall package of the engine would prove beneficial to the chassis designers. The layout's lack of complexity didn't aid Renault initially: from five races entered, they qualified for only four and retired from all with reliability issues. None of the other teams took the venture seriously.

For 1978 the team entered one car for all of the races, posting nine engine related retirements and four classified finishes, which finally brought a fourth place and the team's first points in the US GP East with Jean-Pierre Jabouille at the wheel. For 1979 the team started the season with modified RS01s for Jabouille and Arnoux, and while the car had been developing, reliability was still abysmal with only a few finishes leading up to Monaco. During this time the team had responded to cooling issues both for the engine with an intercooler, but had yet to find the cure for turbo lag. The original layout of a single turbo was proving less suited to European circuits than to US-style ovals, as the driver needed a more immediate throttle response. The long pipe work and heavy single turbo needed a lot of time to spin up to produce power. Under Dudot's guidance the team discarded this layout for a twin turbo design.

Twin Turbo Layout

Renault's Turbo Chassis Development

While the focus was largely on the engine, Renault used their industrial background on the chassis too. The RE20 was a departure for the team in the chassis, discarding the Formula Three-based RS01 and RS10, for a state-of-the-art aluminum monocoque, but with the use of carbon fibre in the chassis, Renault being an unsung pioneer in this field. The top half of the fuel tank was made from carbon fibre. With the turbo engine needing huge amounts of fuel to produce power, the tank sizes in the early eighties were up to 250 litres, resembling a small garden shed behind the driver. Being as high as the driver's shoulders and taking up valuable length this was the drawback of the turbo cars. This offset the gains made from such small engines and only the ever increasing power outputs brought the teams an advantage.

Renault were also quick to understand ground effect, despite the side-mounted turbos and intercoolers taking up space in the profiled sidepods. 1980 and 1981 each brought three wins at high speed tracks were the turbo lag was offset by outright power, while finishes were more common and retirements not solely from engine problems.

1982's RE30 was a smooth design, placing the driver far forward to aid weight distribution required for ground effect, making the fuel tank low and with the cooling now much better managed. The engine was enclosed in the bodywork for the first time. The chassis too was a new development, being a bonded aluminum honeycomb structure, more in keeping with the British Garagiste teams than the Grande Ferrari they were so often compared to. The winter of 1982 saw ground effect banned in favour of flat bottoms, so Renault started the 1983 season with a barely altered RE30 until the RE40 was ready for action.

This was another step for the team in chassis design, an all carbon fibre chassis was presented ahead of much of the British opposition. It used several new solutions: exhaust pipes exiting through the top of the sidepods and over the rear wheel (much similar to today's solutions), and later in the year the team made a major development that has probably also been overlooked. When the top exit exhaust pipes gave some rear tyre overheating problems, a solution that channeled the main secondary exhaust into three, then joined by the wastegate pipe were routed into the diffuser was adopted. Whether by design or accident, Renault created the exhaust blown diffuser; this actually drove the airflow faster under the car giving more downforce and curing a tricky exhaust problem.

No wins from 1984 was repeated in 1985 when the RE60 chassis was a failure and Renault left Formula One as a constructor to supply engines to other teams, even supplying the British Tyrrell team, who had spent much of the start of the eighties protesting the legality of Renault's engine! Renault pressed on as a supplier to three teams, finally pulling out at the end 1986.

Pneumatic Valves

The V10 Engines

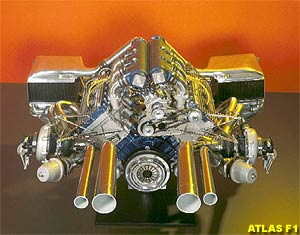

This layout was agreed and Williams were the team to run the new engine in 1989, winning a race in its first season. By then, electronics and the pneumatic valve concept had been much developed and Renault's V10 soon evolved into the standard configuration for F1. Only later in the nineties, after a drop in capacity to 3 litres, did the team ask for lower weight engines and, more importantly, placing the weight lower in the engine. The original V10 placed the cylinders in a V of 72 degrees to get the best crank shaft timing and resulting in a slim engine for aerodynamics. Other teams were creating very light engines and moving to a 90-degree format. Renault-engined Williams and Benettons dominated the sport between 1992 and 1997. But once more Renault left the sport to consider other options and feeling nothing more could be done after their period of superiority. In fact the engine lived on for two years as the Supertech but development had stagnated and was no longer the top of the class.

Renault's Engines Into the New Millennium

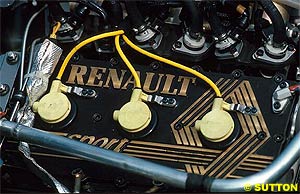

Renault bought the Benetton Formula One team in 2000, as a precursor to returning as a factory team in 2002. Renault once more wanted to highlight its technology as well as to use Formula One to showcase this talent. While other teams were running 72 or 90-degree engines, Renault opted to create a lower engine. While the actual angle has never been disclosed, 106 degrees has been generally accepted as the figure. This wider angle moved the engine lower, crucially lowering the centre of gravity by five-six cms according to Jean Jacques His, the new engine designer. However this gain comes with two costs. The first is the vibrations, the wide angle and V10 format are not naturally balanced so vibrations were initially offset with special firing orders. Secondly the lower engine is wider, this costs in terms of aerodynamics as the wider engine sits in the coke bottle area of car, obstructing routes for cooling air and exhaust to pass through.

In the 2001 car the wider engine overheated, vibrated and blew up too frequently, the chassis was compromised for most part of the season and the car languished at the back of the grid. In 2002, Benetton was renamed as Renault and a new version of the engine and chassis were designed. The engine still had some cooling issue, but the vibrations in the camshafts were the major issue. Reliability suffered, but another by-product of the wide format also manifested itself as a power limiter: the engine's airbox was very wide, which limited the acoustic tuning potential. This allied to the rev restriction to maintain reliability sapped power. Finally in 2003 the RS23 engine adopted two crank driven counter balancers and individual gear drives for each of the camshafts to manage vibrations. Power was still handicapped but reliability improved and the concept was proven just in time for the engine rules to limit the team to one engine per car per weekend. Renault deemed the wide angle engine would not be suitable and have developed a narrower angle engine in its place.

Cam-Less Engine

Elsewhere rumours have circulated about Renault adopting a cam-less design with electro magnetic valve actuation. This in principle would create infinitely variable valve timing and hence the best 'virtual' cam design for each rev band. The practicality of the solution has been deemed too heavy and power sapping for Formula One engines, even if it could cope with the 18-19,000RPM limits. However Atlas F1 have learned that the system is in fact electro-hydraulic using a conventional pneumatic valve return with another hydraulic (or possibly pneumatic) valve opening solution, operating on the same principle. But using a electronic valve controlling the hydraulic circuit in order to alter the lift and duration of the cam's timing. Renault have admitted this system has run on a test engine, but not for racing use. With the change in rules this development may never get to see action.

Chassis Development

OPT

Renault have used motorsport to demonstrate their technology for many years. While other motorsport arenas have seen Renault's participation, it has been Formula One that has seen Renault's greatest input and most influential work, dating back to 1977 with the debut of an all French team from the tyres to the fuel, from the drivers to the chassis.

While the national and European successes were enjoyed, the manufacturer created 'Renault Sport' to develop the various race programmes and based the operation at Viry Chatillon, south of Paris. Key to this strategy was using Turbo charging to develop more power from the V6 engine. Despite the engines initial two-litre capacity, the boost provided by turbo-charging would allow the team to take on the world in categories that had an "equivalency" formula allowing for a smaller turbo engine to run against normally aspirated (i.e. non turbo) engines.

While the national and European successes were enjoyed, the manufacturer created 'Renault Sport' to develop the various race programmes and based the operation at Viry Chatillon, south of Paris. Key to this strategy was using Turbo charging to develop more power from the V6 engine. Despite the engines initial two-litre capacity, the boost provided by turbo-charging would allow the team to take on the world in categories that had an "equivalency" formula allowing for a smaller turbo engine to run against normally aspirated (i.e. non turbo) engines.

Fundamentally a turbocharger is an air pump powered by the force of the exhaust gasses. This allows the pressure of air going into the engine to be increased above the relatively low (just above atmospheric) pressure going into a normal engine. As more air and hence oxygen can be forced into the engine, more power can be generated. The operating principle is the same for most of the turbochargers seen in F1: two fans mounted inside their own pressurised casings are joined by a shaft.

Fundamentally a turbocharger is an air pump powered by the force of the exhaust gasses. This allows the pressure of air going into the engine to be increased above the relatively low (just above atmospheric) pressure going into a normal engine. As more air and hence oxygen can be forced into the engine, more power can be generated. The operating principle is the same for most of the turbochargers seen in F1: two fans mounted inside their own pressurised casings are joined by a shaft.

The Formula One 1.5 litre V6 engine was designed by Dudot with a single turbo charger and tested in a sportscar as far back as 1976. Then in 1977 Renault had decided to build the complete car and built the neat little RS01. The RS01 was a simple Formula One-based aluminum chassis and had aerodynamics partly shaped in the wind tunnel. The car was presented to the press in May and by the European summer had run at a Formula One test in Britain in preparation for the British GP.

The Formula One 1.5 litre V6 engine was designed by Dudot with a single turbo charger and tested in a sportscar as far back as 1976. Then in 1977 Renault had decided to build the complete car and built the neat little RS01. The RS01 was a simple Formula One-based aluminum chassis and had aerodynamics partly shaped in the wind tunnel. The car was presented to the press in May and by the European summer had run at a Formula One test in Britain in preparation for the British GP.

By using two smaller turbos the pipe work could be shortened and the smaller turbos could spin up quicker. This would improve the turbo lag, allied to this 'wastegates' were fitted, acting both as an overboost valve and a bypass valve. When the throttle is lifted the valves open to let the primary exhaust gasses bypass the turbo. That way the turbos keep spinning and are not slowed by the exhaust flow. These developments were introduced at Monaco, initially receiving the name of 'Monaco' spec. Later and more accurately they were badged as the 'twin turbo', and were subsequently run all season and adopted by other teams as they entered the turbo era. This development, allied to the new RS10 chassis, transformed the team's fortunes, and the next race in France saw them win and come third. Suddenly the teapot had become something less than a joke for the other teams.

By using two smaller turbos the pipe work could be shortened and the smaller turbos could spin up quicker. This would improve the turbo lag, allied to this 'wastegates' were fitted, acting both as an overboost valve and a bypass valve. When the throttle is lifted the valves open to let the primary exhaust gasses bypass the turbo. That way the turbos keep spinning and are not slowed by the exhaust flow. These developments were introduced at Monaco, initially receiving the name of 'Monaco' spec. Later and more accurately they were badged as the 'twin turbo', and were subsequently run all season and adopted by other teams as they entered the turbo era. This development, allied to the new RS10 chassis, transformed the team's fortunes, and the next race in France saw them win and come third. Suddenly the teapot had become something less than a joke for the other teams.

It was only in 1982, with the twin turbo much refined and Alain Prost\Rene Arnoux as drivers, that Renault were close to Championship success. By now Ferrari had been campaigning their own turbo engine and BMW had ran their four cylinder turbo engine.

It was only in 1982, with the twin turbo much refined and Alain Prost\Rene Arnoux as drivers, that Renault were close to Championship success. By now Ferrari had been campaigning their own turbo engine and BMW had ran their four cylinder turbo engine.

Also around 1983 was the creation of super fuels. Up until then teams had run pretty standard race fuel, but in 1983 both BMW and Renault used special brews to boost power output. Renault with their Elf fuel mix narrowly lost the Championship and many people still believe BMW had overstepped the rules on their fuel chemistry to bring home the Championship at the end of the season. If 1983 was the closest Renault got to winning the Championship then 1984 was the mark of the end of their run of success as a manufacturer. The RE50 was a neat enough chassis, adopting the Ferrari\ATS design of a bodywork-less monocoque. Also the twin turbo engine had come of age, even then being supplied to Lotus as customer team. But the opposition had caught up and Renault were becoming embroiled in internal politics slowing the team's ability to change rapidly.

Also around 1983 was the creation of super fuels. Up until then teams had run pretty standard race fuel, but in 1983 both BMW and Renault used special brews to boost power output. Renault with their Elf fuel mix narrowly lost the Championship and many people still believe BMW had overstepped the rules on their fuel chemistry to bring home the Championship at the end of the season. If 1983 was the closest Renault got to winning the Championship then 1984 was the mark of the end of their run of success as a manufacturer. The RE50 was a neat enough chassis, adopting the Ferrari\ATS design of a bodywork-less monocoque. Also the twin turbo engine had come of age, even then being supplied to Lotus as customer team. But the opposition had caught up and Renault were becoming embroiled in internal politics slowing the team's ability to change rapidly.

As turbo engine development continued in the eighties, heat problems were ironed out with better materials, oils and design. Turbo lag was eased with shorter pipe lengths and efficient waste gates. Even fuel economy was improved through the use of electronics to counter the fuel consumption formula of the late eighties. But as these problems were cured the engines created ever more power at ever higher revs. Such was the tight confines of the 1.5 litre engine's cylinder head and with the heat from a 1000BHP, valve springs were failing and metallurgy was failing to keep up with the demands placed on the critical springs. Still under Dudot's technical guidance, Renault developed a pneumatic method of returning the valves to close. Replacing the spring with a sealed chamber pressurised by nitrogen gas held on an on-board cylinder, the piston in the chamber acted as a spring without the issue of fatigue or breakage. This development, like so many of Renault's, was at first overlooked until the turbo engines were banned and normally aspirated engines of 3.5 litres were adopted, and rev ceiling went even higher making valve springs a major limitation in the pursuit of power.

As turbo engine development continued in the eighties, heat problems were ironed out with better materials, oils and design. Turbo lag was eased with shorter pipe lengths and efficient waste gates. Even fuel economy was improved through the use of electronics to counter the fuel consumption formula of the late eighties. But as these problems were cured the engines created ever more power at ever higher revs. Such was the tight confines of the 1.5 litre engine's cylinder head and with the heat from a 1000BHP, valve springs were failing and metallurgy was failing to keep up with the demands placed on the critical springs. Still under Dudot's technical guidance, Renault developed a pneumatic method of returning the valves to close. Replacing the spring with a sealed chamber pressurised by nitrogen gas held on an on-board cylinder, the piston in the chamber acted as a spring without the issue of fatigue or breakage. This development, like so many of Renault's, was at first overlooked until the turbo engines were banned and normally aspirated engines of 3.5 litres were adopted, and rev ceiling went even higher making valve springs a major limitation in the pursuit of power.

Once the rules stabilised and the 3.5 litre formula was adopted, Renault announced a return to Formula One in 1988. Initially the team decided a return as an engine supplier was the route to take: embryonic designs and layouts for a 3.5l engine were discussed, but at this stage no team was selected to run the engines. Dudot and his design team spoke to many chassis designers about the requirements in modern Formula One of the time. Engine length, weight and stiffness were cited as main concerns and Dudot used this information to decide on the V10. This was not a natural engine layout due to the harmonics of the odd firing order and crank shaft timing. But the V10 would be a larger but more powerful engine than the V8 Ford was still running, but shorter than the V12, despite less power potential.

Once the rules stabilised and the 3.5 litre formula was adopted, Renault announced a return to Formula One in 1988. Initially the team decided a return as an engine supplier was the route to take: embryonic designs and layouts for a 3.5l engine were discussed, but at this stage no team was selected to run the engines. Dudot and his design team spoke to many chassis designers about the requirements in modern Formula One of the time. Engine length, weight and stiffness were cited as main concerns and Dudot used this information to decide on the V10. This was not a natural engine layout due to the harmonics of the odd firing order and crank shaft timing. But the V10 would be a larger but more powerful engine than the V8 Ford was still running, but shorter than the V12, despite less power potential.

As part of the wide angle engine layout, Renault have gone their own way with chassis design. Making the car's centre of gravity as low as possible has been a preoccupation for former technical director Mike Gascoyne for several years. Even into 2003 a lightweight gearbox made from carbon fibre and titanium was introduced, while aerodynamic work has seen the car's lack of power combated with ultra low drag designs, even the cooling package has evolved aerodynamic solutions to pull hot air for the sidepods by the vortex trailing from the winglet ahead of the chimney. Finding yet more ways to yield gains from the engine has encompassed electronics: the Renault traction and launch control systems are rated as the best, and use clutch slip as part of the launch control strategy, giving the team the best starts on the grid.

As part of the wide angle engine layout, Renault have gone their own way with chassis design. Making the car's centre of gravity as low as possible has been a preoccupation for former technical director Mike Gascoyne for several years. Even into 2003 a lightweight gearbox made from carbon fibre and titanium was introduced, while aerodynamic work has seen the car's lack of power combated with ultra low drag designs, even the cooling package has evolved aerodynamic solutions to pull hot air for the sidepods by the vortex trailing from the winglet ahead of the chimney. Finding yet more ways to yield gains from the engine has encompassed electronics: the Renault traction and launch control systems are rated as the best, and use clutch slip as part of the launch control strategy, giving the team the best starts on the grid.

Michelin are still Renault's tyre supplier having both debuted in Formula One together back 1977. Now Michelin are providing input into the chassis side. Having developed suspension systems to keep the tyres in flat contact with the ground regardless of the car's roll angle, Michelin patented the systems and provided them to their F1 partners for evaluation. Renault ran their version of OPT late in 2002 and throughout early 2003. Using the suspension system on the rear of the car, Renault have completed many days of testing with the system. While the gains are said to be considerable, no race debut for the set up was planned this year and recently the FIA have indicated to Michelin and Renault the set up would not be accepted in Formula One as the rules currently stand, closing a potential advantage for the two companies.

Michelin are still Renault's tyre supplier having both debuted in Formula One together back 1977. Now Michelin are providing input into the chassis side. Having developed suspension systems to keep the tyres in flat contact with the ground regardless of the car's roll angle, Michelin patented the systems and provided them to their F1 partners for evaluation. Renault ran their version of OPT late in 2002 and throughout early 2003. Using the suspension system on the rear of the car, Renault have completed many days of testing with the system. While the gains are said to be considerable, no race debut for the set up was planned this year and recently the FIA have indicated to Michelin and Renault the set up would not be accepted in Formula One as the rules currently stand, closing a potential advantage for the two companies.

Please Contact Us for permission to republish this or any other material from Atlas F1.