Atlas F1 Technical Writer

Atlas F1 reveals one of the biggest secrets kept under the hood, the OPT system invented by Michelin and now tested by Renault. The new suspension system, considered one of the most important developments to arrive in Formula One for many years, may have a major impact on lap times in the future - and with Renault's head start on development, the French team could well be on their way to make history. Craig Scarborough explains how OPT works and why it's going to be the new magic word. Exclusive for Atlas F1

However, recent documents obtained by Atlas F1 - among them Michelin's registered patent of OPT for road cars - shed significant light on the system, allowing us to exclusively expose how OPT works.

In a nutshell, OPT is a mechanical suspension device permitting camber - or in other words, a type of suspension system that puts the tyre in the best contact with the ground. This contact is lost when a normal car leans over in a corner, but OPT uses a complex linkage that keeps the wheel upright even when the car is tilted in a corner.

Designing this complex system is a feat in itself and the difficult job of making it fit into the tight confines of an F1 car demonstrates the potential gains possible from this system. Michelin have been working on the innovation for several years now. Their achievement is considered remarkable not only for racing cars but also for road cars. A system that allows more road grip is a system that offers more safety. In Formula One terms, that system can also translate into significant improvement in lap times; in cornering performance; in acceleration and braking; as well as improving the wear from the tyres.

Michelin offered the system to several of its partnered teams, but so far Renault have been the only ones to commit to it, although the French team have yet to run the system at a Grand Prix. In fact, the system is not likely to show up in a race before next year, but Renault certainly have a head start on the development of the system over the other Michelin teams, boding well for the team when driver-aids are once again banned.

Building Cars for Tyres

By and large, the tyres have always been built for the cars and not vice-versa. However, the most crucial gain in lap times of the past couple of years came from improved tyres - these can gain whole seconds per lap, while aerodynamic or engine developments only produce improvements of tenths or even thousandths of a second. Therefore, a suspension system designed in accordance with the tyre manufacturer makes a lot of sense.

When the French tyre manufacturer began talking about their patented suspension system, which could take advantage of a new breed of tyres, the teams sat up and took notice. As last season progressed, Michelin became increasingly critical in its declarations, stating that its supplied teams would not make a major gain in pace without the new system. This was put down by some as an excuse for Michelin's failure to meet Bridgestone on equal terms in all the 2002 races, with very little credence given to this mysterious system breaking cover any time soon.

However, in mid-2002, Michelin filed in several countries for a patent on their new suspension system. Their application was approved in the end of 2002, and the OPT system is now a registered patent, owned by the French tyre maker (or, more specifically, by its R&D office in Switzerland).

Patent applications are incredibly detailed documents. They need to be detailed, or anyone copying the innovation could claim to have made it different in one way or another. So a patent document includes minute details of how a system works and, in Michelin's case, it also includes images and drawings. A careful study of these documents, along with up-close and technical study of the Renault car in recent testing session reveal that Michelin's claims last year - and their declarations - could very well hold some substance.

A Solution to a Problem

An F1 car's suspension system is designed to control the movement of the wheel in three dimensions in order to keep the tyre in best contact with the track. This three dimensional movement is dictated by the suspension geometry.

All suspension systems are compromised by many factors - primarily by the FIA rules which dictate that the suspension must be fully mechanical and not use the hydraulics from the active area to alter the geometry. Designers have to create a light suspension system with a low frontal area for better aerodynamics, as well as make it strong enough to withstand the aerodynamic loads and move the wheel within a relatively controlled geometry.

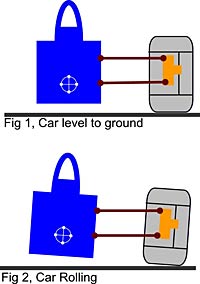

For many years now, F1 suspension systems have used a double wishbone arrangement. This meets all the criteria above, but its geometry is limited. Double wishbone suspension uses two V-shaped links to link the car to the wheel, and placed one above the other, the wishbones (Fig1, Brown) mount to the chassis (Fig1, Blue) at their pointed end to an upright (Fig1, orange). Viewed from the front, this forms a parallelogram, so as the wheel moves its relationship to the chassis is determined by the fixed length wishbones.

One area where this geometry is limiting, is in the roll. Coming out of a corner, an F1 car is trying to roll, lifting the inside edge of the tyre off the track and limiting the grip for cornering and acceleration. If the rear wheels could be kept flatter to the ground, more grip would be possible and more traction could be gained. This is not possible with current F1 suspension - the lifting of the inside edge of the tyre is inherent to its design.

In fact, we have all experienced roll in our road cars: as a car corners, it tends to roll from the top towards the outside of the corner. This roll is created by centrifugal forces acting on the car's centre of gravity (Fig1, White cross), which in turn rolls the car around an imaginary point called the roll centre.

When a car rolls, weight is moved to the outside wheels. This reduces the weight placed on the inside wheels and hence these wheels cannot provide as much grip, as they are in less secure contact with the ground.

With the combined loss of grip from weight shift and camber change, the car has a reduced ability to corner just when it needs it most. Weight shift can be managed by the car's antiroll bars and by reducing the centre of gravity. But camber change needs to be cured by a different geometry within the suspension, and without the option of an active solution, a mechanical route needs to be found. Michelin's system offers a solution to this problem.

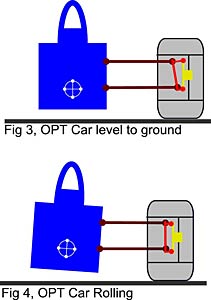

Currently, as a chassis rolls (Fig2), the upper wishbones move across more than the lower wishbone does, making the wheel tilt and lifting its inside edge off the road. As the double wishbone suspension uses fixed length wishbones, this cannot be avoided. One solution is to alter the effective length of these links as the car rolls. OPT achieves this by using a two-piece upright (Fig3, Red and Yellow).

The inner upright (Fig3, Red) is connected to the wishbones and controls the camber change in the outer upright (Fig3, Yellow), which carries the wheel and brakes. The two uprights are hinged together with unequal length links - the inner upright is also pivoted between the wishbones, and as the car rolls (Fig4) the inner upright pivots, moving the longer upper link inwards and shortening the effective length of the upper wishbone. This keeps the wheel at a more consistent camber angle.

In order to accomplish this, the toe link (Fig3, grey) used to keep the rear wheel in a straight-line (or in 'toe') is used to both turn the inner upright and keep the outer upright pointing in a straight line. While this is in essence a simple system, the calculation of the geometry to allow a system that both controls 'camber' and 'toe' can only realistically be achieved with computers that derive the correct lengths for all the links.

In Search of OPT

Dupasquier confirmed that OPT exists not just for race cars but "for tyres and cars in general" with the theory that it would "minimise the change in position of the tyre on the ground." He explained that for a tyre to work you need to control "the position of the tyre on the ground and the load," hence with OPT controlling the tyres position and the use of "an ambitious radial (tyre) concept" you can gain more performance from the radial tyre's inherent structural stiffness.

When I asked him whether the solution was a mechanical or active type of technology, Dupasquier replied: "We are not allowed to electronically adjust anything in the suspension; it's in the way the suspension is designed." So if the suspension compensates for changes in the car's position (roll), would the tyre not be affected? "That's the target," he confirmed. Had any of the teams taken up this solution? "It's something we've worked on and made available to our partners," he said, but refused to reveal whether any of them adopted it. "It's up to them!" he exclaimed.

Gascoyne was no less coy about the system. "We ran it [in Barcelona]," he merely admitted. "We did suspension testing on the old car and will continue to do so." I told Gascoyne that when I attended the Barcelona test, I noticed an unusual rear wheel, with a shallow offset, somewhat similar to that run by Toyota on their 2001 test car. Was that related to the OPT system, I asked him? "Possibly…" came the short answer, signalling that was all the information he was willing to divulge.

It now seems Renault have been running OPT - or OCP as they prefer to call it - on a test chassis based on the last year's R202. Aside from the increased telemetry fitted and the rear suspension, it is a standard car. It was run twice in Barcelona and once at a shortened Silverstone circuit in the hands of Allan McNish.

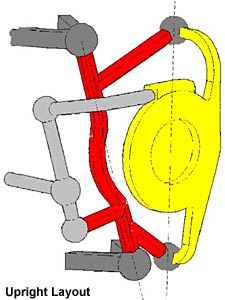

Renault use a two piece "hinged" rear upright that compensates the tyres for the roll of the chassis. This prevents the lifting of the inside edge of the tyre and should give both greater grip and less tyre wear. To house this larger rear upright and the rocker to operate it, the team use a large rear brake duct and deeper rear wheel. The brake duct features what appears to be a large scoop but is in fact a fake - it's there to hide the rocker linkage from prying eyes.

Renault hired Allan McNish as their third driver primarily because he's been working with Michelin on the Toyota program for two years. The French team, along with Michelin, are still developing the system and it is not yet race ready - they need to learn a completely new way to set up the rear suspension geometry and it may be some time before it is refined and outpacing the R23's conventional suspension. But when it is at that stage, the set up could be transferred to the new R23 quite easily.

As the hardware required for OPT is largely placed at the end of the suspension inside the rear wheel, no other major components would need to be re-engineered. Seeing as Renault have a limit on testing this year and as they have other more pressing testing requirements to get the R23 and its engine up to speed, it's doubtful that enough progress can be made to get OPT ready to race this year.

However, for next year, with the ban on driver aids eradicating traction control, the traction benefits of OPT may well pay off for the team. And if Michelin's patent is successfully adapted to Formula One, don't be surprised to see Renault making a quantum leap towards World Championship challenge in the upcoming couple of years.

Renault have been the source of many rumours since they returned to Formula One and more so lately, as the French team are visibly moving up the grid and fighting with the traditional top teams for podium places and race leads. Whether it's speculations about radical engine concepts or flexing bodywork, many of these rumours have been unfounded while some of the true innovations being developed by the team have been overlooked.

Since late last year, Renault have been testing a new rear suspension system that originates from Michelin, a system called OPT - acronym for its French name, which translates to Optimum Contact Patch. Little information has been available on this system, and other than acknowledging its existence Renault and Michelin have been secretive on how OPT works and what gains could be made by it.

Since late last year, Renault have been testing a new rear suspension system that originates from Michelin, a system called OPT - acronym for its French name, which translates to Optimum Contact Patch. Little information has been available on this system, and other than acknowledging its existence Renault and Michelin have been secretive on how OPT works and what gains could be made by it.

Michelin's return to Formula One three years ago marked the beginning of a fierce tyre war, which in turn lead to a sharp decrease in lap times along with increase of cornering speeds. Tyre development has been centred mainly on improvement of compounds and constructions, while teams have tweaked their cars to suit newly developed tyres from both of the rubber makers.

Michelin's return to Formula One three years ago marked the beginning of a fierce tyre war, which in turn lead to a sharp decrease in lap times along with increase of cornering speeds. Tyre development has been centred mainly on improvement of compounds and constructions, while teams have tweaked their cars to suit newly developed tyres from both of the rubber makers.

An F1 car has to translate all its power, braking and downforce to the road via the four small contact patches between the tyre and the road. The art of keeping the tyres in better contact with the ground has been largely obtained through downforce and refinement of existing suspension designs.

An F1 car has to translate all its power, braking and downforce to the road via the four small contact patches between the tyre and the road. The art of keeping the tyres in better contact with the ground has been largely obtained through downforce and refinement of existing suspension designs.

The other result of roll is the angle of the contact patch of the tyre to the ground. When a car is stationery, the wheel is placed at a fixed angle to the ground. This is known as the camber angle (Fig1). As a car rolls, the suspension pushes the wheel to a different angle (Fig2). This change in camber makes the contact patch smaller and more grip is lost.

The other result of roll is the angle of the contact patch of the tyre to the ground. When a car is stationery, the wheel is placed at a fixed angle to the ground. This is known as the camber angle (Fig1). As a car rolls, the suspension pushes the wheel to a different angle (Fig2). This change in camber makes the contact patch smaller and more grip is lost.

After the winter testing ban, reports in the media declared Renault were running OPT in one of the first tests in Barcelona. I had the first chance to inquire about the system at Renault's second launch, in Paul Ricard, where I met with both the technical directors for Michelin and Renault, Pierre Dupasquier and Mike Gascoyne.

After the winter testing ban, reports in the media declared Renault were running OPT in one of the first tests in Barcelona. I had the first chance to inquire about the system at Renault's second launch, in Paul Ricard, where I met with both the technical directors for Michelin and Renault, Pierre Dupasquier and Mike Gascoyne.

Please Contact Us for permission to republish this or any other material from Atlas F1.

|

Volume 9, Issue 14

Atlas F1 Exclusive

The French Connection: OPT Uncovered

Pizzonia: From Jungle to Jungle

Giancarlo Fisichella: Through the Visor

Articles

Karl Kling: An Appreciation

2003 Brazilian GP Preview

2003 Brazilian GP Preview

Between the Lakes

Brazilian GP Facts & Stats

Columns

The 700th GP Trivia Quiz

Bookworm Critique

On the Road

Elsewhere in Racing

The Weekly Grapevine

> Homepage |